2025 Guide: How to Choose the Right Wire Tray for Your Projects

In the ever-evolving landscape of electrical infrastructure, the choice of a suitable wire tray becomes paramount for ensuring both efficiency and safety in your projects. As emphasized by industry expert John Smith, “Selecting the right wire tray is not just about aesthetics; it’s a critical decision that impacts the durability and performance of your electrical systems.” With various materials, designs, and capacities available, understanding the intricacies of wire trays can significantly enhance project outcomes.

Wire trays play an essential role in managing cables and wires, providing a structured support system that facilitates organized installations. Choosing the appropriate wire tray not only improves accessibility and maintenance but also minimizes the risk of damage to your electrical lines. It is crucial for project managers and engineers to consider the specific needs of their installations, including load requirements, environmental conditions, and compliance with local codes.

This guide aims to provide insights and practical advice on how to navigate the myriad options available in the wire tray market, helping you make informed decisions for successful project execution. By understanding the fundamentals of wire tray selection, you can ensure that your electrical systems are not only functional but also built to last.

Understanding Different Types of Wire Trays Available in the Market

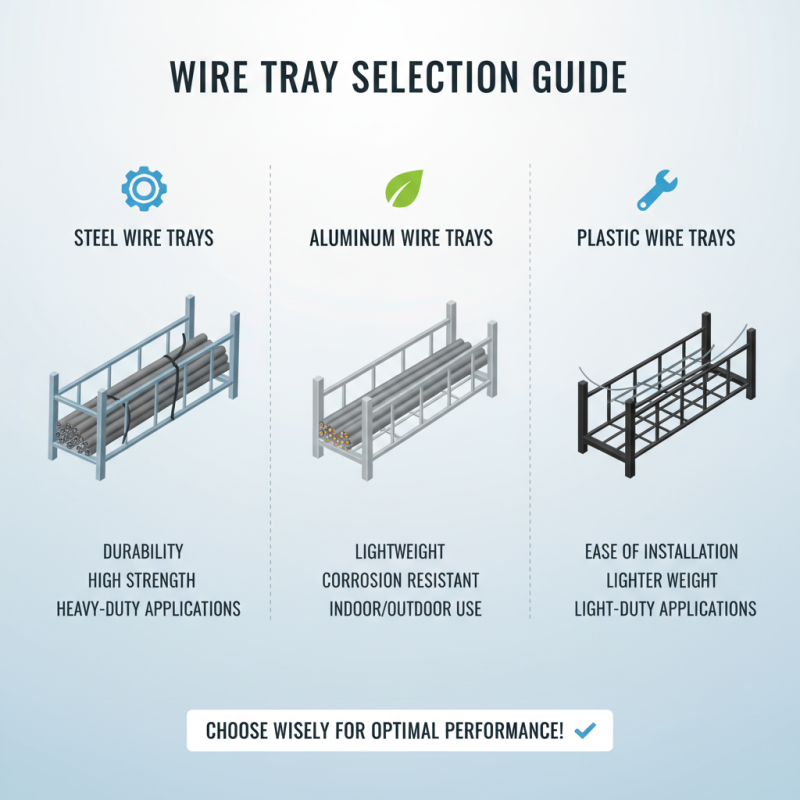

When selecting a wire tray for your projects, it’s essential to understand the various types available in the market to ensure optimal performance and compatibility with your needs. Wire trays come in different materials, including steel, aluminum, and plastic. Steel wire trays are known for their durability and strength, making them ideal for heavy-duty applications. Aluminum trays offer a lighter alternative with good corrosion resistance, suitable for both indoor and outdoor use. Plastic trays, on the other hand, are typically used in lighter applications and provide ease of installation due to their lighter weight.

Furthermore, wire trays are categorized based on their design and functionality. Ladder trays feature a side rail with rungs, providing a robust structure for supporting heavier cables. Channel trays have a solid bottom, making them suitable for applications where dust and debris can accumulate, effectively providing protection for the cables inside. Additionally, there are wide and narrow options available, depending on the volume of wires you need to manage. Understanding these differences will help you make an informed decision, catering to the specific requirements of your project while enhancing safety and organization.

Key Factors to Consider When Choosing Wire Trays for Your Projects

When selecting wire trays for your projects, several key factors should be considered to ensure functionality and durability. Firstly, the material of the wire tray plays a crucial role in its application. Common materials include steel, aluminum, and plastic, each having distinct advantages. Steel trays offer high durability and load-bearing capacity, making them ideal for heavy-duty applications. Aluminum, being lightweight and resistant to corrosion, is suitable for outdoor installations or environments prone to moisture. Conversely, plastic trays are often used in smaller, less demanding setups, providing ease of handling and installation.

Another critical factor to consider is the size and design of the wire tray. It is essential to assess the amount and types of cables that will be accommodated, as well as the layout of the installation area. Opting for adjustable designs might provide flexibility for future expansions or changes in the project. Additionally, ensure that the trays are compliant with any applicable local or national regulations regarding electrical installations and safety standards. Proper planning in these areas will contribute to a more efficient and secure outcome for your wiring needs.

Material Options: Comparing Metal and Plastic Wire Trays

When selecting a wire tray for your projects, the material plays a crucial role in determining the performance, longevity, and suitability for specific environments. Metal wire trays, typically made from steel or aluminum, offer significant strength and durability. They are resistant to high temperatures and impact, making them ideal for industrial settings where heavy cables are common. Additionally, metal trays can be treated for corrosion resistance, which is essential in environments exposed to moisture or chemicals. Their robust nature also allows for easy integration of heavy load-bearing structures, ensuring that cables are safely and securely organized.

On the other hand, plastic wire trays provide a lightweight and cost-effective alternative. They are ideal for residential or low-load applications, where flexibility and ease of installation are prioritized. Plastic trays are often resistant to corrosion and do not conduct electricity, offering an added layer of safety in certain situations. Their versatility allows them to be used in various settings, from home wiring projects to small office installations.

However, it's important to note that while plastic trays can handle lighter loads, they may not withstand the same level of stress as their metal counterparts. Ultimately, the choice between metal and plastic wire trays should be guided by the specific requirements of your project. Consider the environment, load capacity, and installation ease to determine the best option that will meet your needs efficiently.

Sizing and Capacity: Determining the Right Dimensions for Your Needs

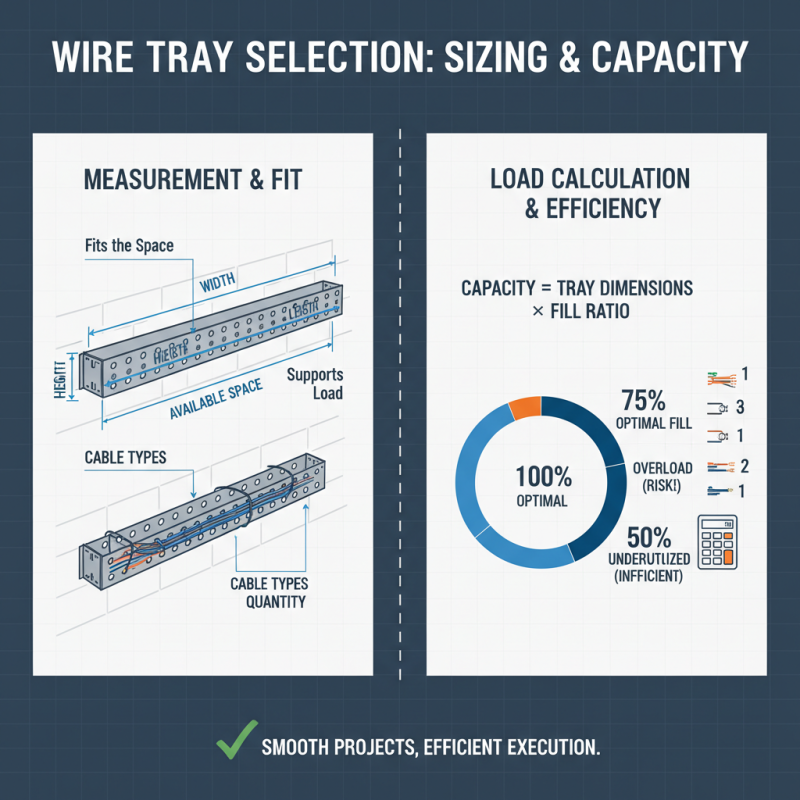

When it comes to selecting the right wire tray, understanding sizing and capacity is crucial for ensuring that your projects are executed smoothly and efficiently. The size of the wire tray directly affects its ability to accommodate various types of cables and wiring systems. A precise measurement ensures that the tray not only fits the space available but can also support the expected load without compromising safety or performance. Run your calculations based on the number and type of cables you plan to use, as well as the tray's dimensions to avoid overloading or underutilizing the tray.

Tips for determining the right size include measuring the total cable volume you anticipate needing and consulting relevant guidelines for spacing and separation of various cable types. Keep in mind that the width and depth of the wire tray should provide ample space for cable management practices, promoting airflow and reducing heat build-up. Assessing the future expansion of your project can also influence your size selection; planning for growth can save time and costs down the line.

Additionally, consider the environment where the tray will be installed. Factors such as exposure to the elements or potential interference from other systems can affect your choice of material and design. Choose a wire tray size that not only fits your current needs but can also adapt to changes over time, ensuring longevity and reliability in your cable management system.

Installation Tips and Best Practices for Wire Tray Usage

When selecting a wire tray for your projects, understanding the installation tips and best practices is crucial for ensuring both safety and efficiency. According to the National Electrical Contractors Association (NECA), proper installation of wire trays can enhance the lifespan of wiring systems by as much as 30% when compared to less organized solutions. This longevity is mainly attributed to the reduced strain on cables and minimal exposure to environmental factors. Using the right tools and following manufacturer guidelines are fundamental to achieving optimal results during installation.

While installing wire trays, it's essential to maintain appropriate spacing and secure the trays adequately. The National Fire Protection Association (NFPA) recommends that wire trays be installed at least 12 inches apart on vertical spans to allow for heat dissipation, thereby minimizing the risk of overheating and electrical failures. Properly securing the trays with support brackets at recommended intervals not only ensures stability but also facilitates easier access for future maintenance.

By adhering to these best practices, professionals can significantly reduce installation errors and enhance overall project efficiency, leading to safer and more reliable electrical systems.

Related Posts

-

Mastering Cable Pulling Tools: Essential Techniques for Efficient Installation and Maintenance

-

Understanding the Essentials of Wiring Looms: A Guide to Simplifying Your Projects

-

Top 5 Benefits of Using High-Quality Cable Harnesses for Your Projects

-

How to Use a Wire Snake for Effective Clog Removal in Your Plumbing System

-

How to Use Wire Ties Effectively for Organizing and Securing Items

-

Top 5 Wire Zip Ties to Enhance Your Organization and DIY Projects in 2025