4 AWG THHN Wire Best Applications and Installation Tips You Need to Know

When it comes to electrical wiring, selecting the right gauge is crucial for ensuring safety and efficiency. Among the various options available, the 4 AWG THHN wire stands out due to its versatility and reliability. This particular type of wire is commonly used in a variety of applications, ranging from residential wiring to industrial settings, making it a staple for electricians and DIY enthusiasts alike. Its unique construction allows it to withstand high temperatures and various environmental conditions, which is essential for maintaining optimal performance.

In this guide, we will explore the best applications for 4 AWG THHN wire and provide essential installation tips to help you make the most of this robust wiring solution. Whether you are planning to wire heavy machinery, install electrical panels, or run circuits for large appliances, understanding the proper usage and installation techniques of 4 AWG THHN will enhance your project's safety and efficiency. Join us as we delve into the key aspects that make this wire a preferred choice for many electrical applications.

Applications of 4 AWG THHN Wire in Residential Electrical Systems

4 AWG THHN wire is widely recognized for its versatility and reliability, making it an excellent choice for various residential electrical applications. This gauge is particularly well-suited for circuit feeds that require substantial current capacity, such as branch circuits for large appliances, HVAC systems, and other heavy-duty electrical installations. Its ample conductor size allows for a significant load, ensuring that your home’s electrical systems operate efficiently without the risk of overheating or voltage drops.

When installing 4 AWG THHN wire, it is essential to follow specific guidelines to maximize safety and performance. First, ensure that you use the appropriate conduit, as THHN is designed for both dry and damp locations but must be protected in wet areas. Also, pay attention to the ambient temperature; THHN wire can handle high temperatures, but it’s advisable to check local codes for maximum ampacity in various conditions.

Additionally, always strip the wire to the right length and secure connections firmly to prevent loose wires, which can lead to short circuits or fire hazards. Remember to double-check connections with a multimeter before energizing the circuit. Proper insulation and securing the wire away from sharp edges or potential snags are also crucial to enhance longevity and safety in your home’s wiring systems.

4 AWG THHN Wire Best Applications and Installation Tips

| Application | Installation Tips | Environment Suitability | Voltage Rating |

|---|---|---|---|

| Residential Wiring | Ensure proper conduit usage to protect from moisture. | Indoor and dry locations. | 600 volts. |

| Electrical Feeders | Follow local codes for wire sizing and installation. | Underground or protected outdoor use. | 600 volts. |

| Circuits for Appliances | Use proper breakers to prevent overload. | Indoor and temperature-controlled spaces. | 600 volts. |

| Lighting Circuits | Maintain appropriate wire length to avoid voltage drop. | Indoor, protected from water exposure. | 600 volts. |

Industrial Uses of 4 AWG THHN Wire: Connecting Heavy Machinery

The 4 AWG THHN wire is an essential component in the industrial sector, particularly when it comes to connecting heavy machinery. This wire, which can handle a substantial current capacity up to 95 amps in a conduit at moderate temperatures, is highly favored for its durability and versatility. According to the National Electrical Code (NEC), the 4 AWG THHN wire is suitable for a wide range of applications, including service feeders, branch circuits, and industrial equipment wiring. Its ability to withstand high temperatures—up to 90 degrees Celsius—makes it particularly useful in environments where heat and friction are major concerns, such as in factories and manufacturing units.

When installing 4 AWG THHN wire, several best practices can ensure safety and efficiency. First, it is crucial to assess the specific current load and ambient temperature where the wire will be used, as these factors significantly influence performance. Additionally, proper conduit use can prolong the lifespan of the wire by protecting it from mechanical damage and extreme environmental conditions. The National Fire Protection Association (NFPA) emphasizes that adhering to proper installation techniques not only enhances operational reliability but also minimizes risks associated with electrical failures, which can lead to costly downtime and safety hazards. By following these guidelines, industries can effectively harness the potential of 4 AWG THHN wire for their heavy machinery applications.

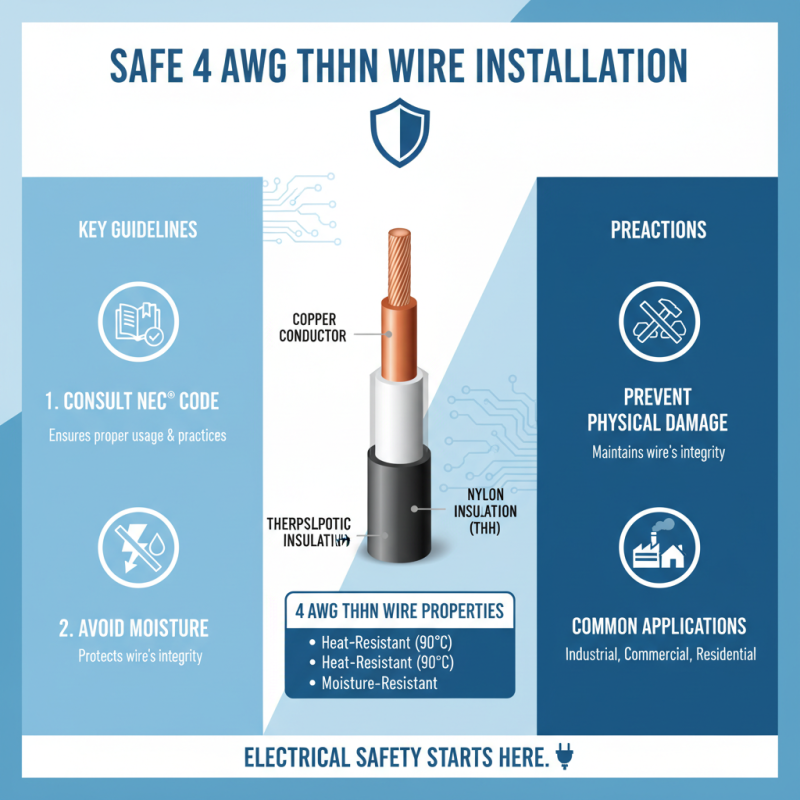

Safety Standards for Installing 4 AWG THHN Wire: What You Need to Know

When installing 4 AWG THHN wire, adhering to safety standards is crucial to ensure a secure and efficient electrical system. First and foremost, it’s essential to consult the National Electrical Code (NEC) guidelines, which dictate the appropriate usage and installation practices for various wire types, including THHN. This wire, known for its heat-resistant and moisture-resistant properties, is commonly used in industrial, commercial, and residential applications. However, to avoid potential hazards, it is vital that the installation area is free from exposure to excessive moisture and physical damage, as these conditions can compromise the wire’s integrity.

Additionally, proper securing methods must be employed during installation to minimize the risk of electrical hazards. Using suitable connectors and support systems, such as cable trays or conduits, ensures that the wire is adequately protected and organized. Moreover, when making electrical connections, maintaining the correct torque specifications for terminals is necessary to prevent overheating and subsequent electrical failures. Always use Personal Protective Equipment (PPE) when handling electrical wiring to further safeguard oneself against possible accidents. By following these safety standards, you can enhance the reliability of your electrical systems while ensuring safety for all involved.

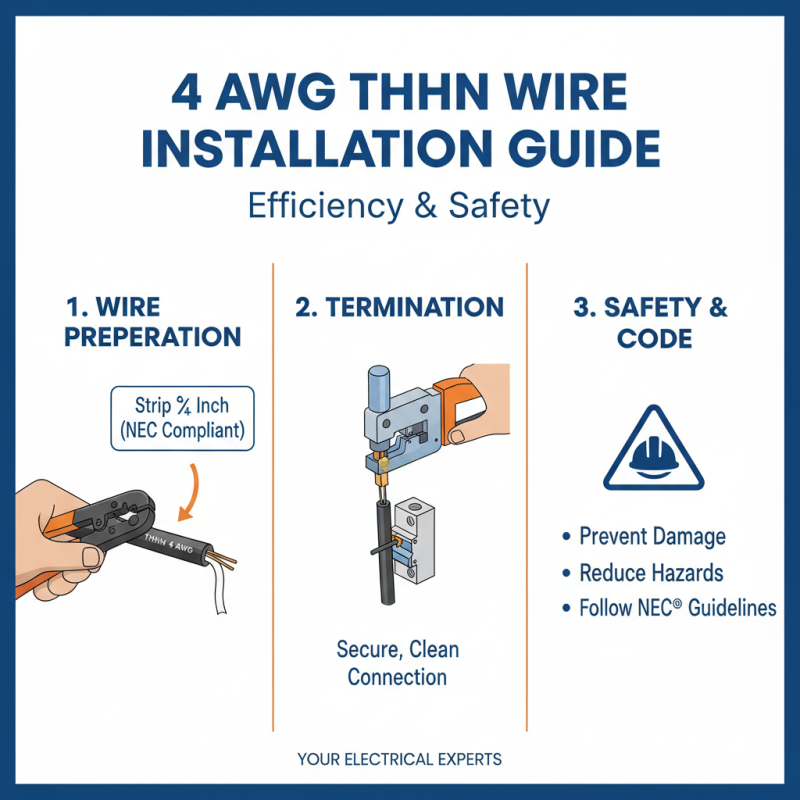

Optimal Installation Techniques for 4 AWG THHN Wire: A Step-by-Step Guide

When it comes to installing 4 AWG THHN wire, understanding the optimal techniques can significantly enhance both efficiency and safety. This wire type, recognized for its excellent conductivity and heat resistance, is widely used in residential and commercial applications. The first step in a successful installation involves ensuring proper wire stripping and termination. For 4 AWG THHN wire, it is recommended to strip about ¾ inch of insulation from the end, ensuring a clean and effective connection. According to the National Electrical Code (NEC), following the correct stripping guidelines helps prevent wire damage and potential hazards.

Another vital consideration is the installation environment. 4 AWG THHN wire is rated for environments up to 90°C, making it suitable for most applications, but it is essential to assess any potential exposure to moisture or chemicals. To manage this, utilize conduit installations in settings that may subject the wire to adverse conditions. Additionally, proper routing of the wire is crucial. It should be run in a manner that avoids tight bends, which can lead to wire fatigue over time.

**Tips for Installation:** Always use appropriate connectors for the 4 AWG THHN wire, as using incompatible connectors can lead to overheating and electrical failures. Ensure that the wire is securely fastened with cable clamps at intervals recommended by the NEC, which usually suggests not exceeding 10 feet between supports. Maintaining a clean and dry working environment also contributes to a safer installation, reducing the risk of damaging the wires or compromising their effectiveness. Employ these practices to optimize both the performance and longevity of your 4 AWG THHN installations.

Comparative Analysis of 4 AWG THHN Wire vs. Other Wiring Sizes

When comparing 4 AWG THHN wire to other wire sizes, it's essential to consider its current-carrying capacity and applications. The 4 AWG THHN wire is rated for a maximum of 70 amperes in a typical conduit, making it suitable for residential and commercial electrical installations, especially for feeding sub-panels, large appliances, and motor circuits. According to the National Electrical Code (NEC), proper wire sizing is crucial for preventing overheating and ensuring safety in electrical systems. When compared to 6 AWG wire, which is rated for only 55 amperes, the 4 AWG offers a significant advantage in situations requiring higher amperage.

Furthermore, the advantages of using 4 AWG THHN wire extend to its versatility in different environments. It is designed to endure high temperatures, moisture, and potentially corrosive elements, which makes it preferable in both indoor and outdoor installations. Industry reports highlight that wires with larger gauges, like the 4 AWG, not only provide reduced voltage drop over long distances but can also enhance system efficiency. For instance, using 4 AWG instead of 10 AWG wire for a long-run application can result in up to 10% less energy loss, which contributes to lower energy costs over time. This demonstrates the importance of selecting the appropriate wire size to optimize energy efficiency while ensuring safety and performance in installations.

4 AWG THHN Wire Applications Comparison

This chart illustrates the current carrying capacity of 4 AWG THHN wire in different applications. As shown, the wire performs effectively in various settings, including residential, commercial, and industrial environments.

Related Posts

-

2025's Top 5 THHN Wire Innovations: Essential Choices for Electrical Projects

-

10 Essential Tips for Using THHN Wire in Your Electrical Projects

-

How to Use Wire Ties Effectively for Organizing and Securing Items

-

Mastering Cable Pulling Tools: Essential Techniques for Efficient Installation and Maintenance

-

What are Wire Zip Ties and How to Choose the Right One for Your Project

-

Understanding the Essentials of Wiring Looms: A Guide to Simplifying Your Projects