Top Benefits of Using Tray Cables for Electrical Installations Today

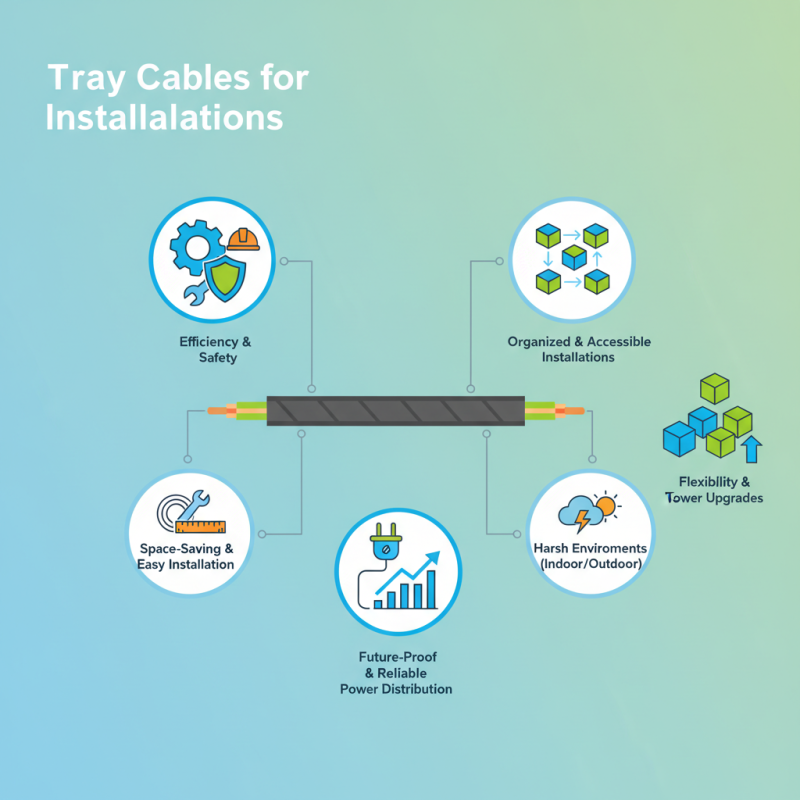

In today's rapidly evolving electrical landscape, the choice of wiring can significantly impact the efficiency and safety of installations. Tray cables, designed for versatility and resilience, have emerged as a preferred solution for various applications, from industrial settings to commercial buildings. These specialized cables are not only adept at withstanding harsh environments but also offer important advantages in terms of space-saving and ease of installation. Utilizing tray cable can streamline wiring processes, reduce labor costs, and enhance the overall performance of electrical systems.

One of the standout features of tray cables is their ability to facilitate organized and accessible installations, which are critical in maintaining the integrity of complex electrical networks. With their robust construction and compliance with industry standards, tray cables provide enhanced protection against environmental factors, making them ideal for both indoor and outdoor use. Moreover, the modular design of tray cable systems fosters greater flexibility, allowing for easy modifications and upgrades, a crucial aspect in an age where technological advancements occur rapidly.

Ultimately, the integration of tray cables into electrical installations not only supports effective management of power distribution but also aligns with modern safety practices. As industries continue to prioritize efficiency and safety, tray cables represent a forward-thinking approach to wiring solutions, ensuring that both current and future electrical needs are met with reliability and ease.

Top Benefits of Using Tray Cables for Electrical Installations Today

Tray cables have become a popular choice for electrical installations across various industries due to their numerous benefits. One of the primary advantages is their versatility. According to a report from the National Electrical Manufacturers Association (NEMA), the demand for flexible wiring solutions has increased by over 25% in the past five years. Tray cables can be used in a variety of applications, including industrial settings, commercial buildings, and outdoor environments, making them suitable for a wide range of projects.

Another significant benefit of tray cables is their ease of installation. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlighted that using tray cables can reduce installation time by up to 30%, compared to traditional wiring methods. This efficiency is largely due to their lightweight design and the ability to run multiple conductors within a single cable, minimizing the need for extensive labor and materials. This not only lowers overall project costs but also enhances the safety of installations, as tray cables are designed to withstand environmental stresses and provide better protection against physical damage.

Furthermore, tray cables contribute to improved performance and reliability in electrical systems. The Wire and Cable Manufacturers Alliance (WCMA) reports that the insulation materials used in tray cables can enhance signal integrity and reduce electromagnetic interference (EMI), which is crucial for sensitive electronic applications. As industries continue to evolve and become more reliant on technology, the reliability offered by tray cables is poised to play a vital role in ensuring optimal performance within electrical installations.

Top Benefits of Using Tray Cables for Electrical Installations Today

| Benefit | Description | Applications |

|---|---|---|

| Flexibility | Tray cables can bend and accommodate various installation layouts easily. | Industrial, Commercial |

| Durability | Designed to withstand harsh environments, including moisture and chemicals. | Manufacturing, Outdoor Installations |

| Cost-Effectiveness | Less expensive to install compared to traditional wiring methods, saving on labor and materials. | Residential, Commercial |

| Ease of Installation | Simplified installation processes due to their lightweight design. | New Construction, Retrofits |

| Safety | Tray cables are designed to minimize electrical hazards, with high-quality insulation. | Utilities, Data Centers |

Enhanced Durability: Understanding Tray Cable Construction and Materials

Tray cables are engineered to meet the demands of electrical installations in a variety of environments, offering enhanced durability due to their specialized construction and materials. Typically composed of multi-conductor designs and insulated with robust thermoset or thermoplastic materials, tray cables are designed to withstand harsh conditions, including exposure to moisture, chemicals, and mechanical stresses. According to a report by the National Electrical Manufacturers Association (NEMA), tray cables exhibit significant resistance to abrasion and environmental degradation, which enhances their longevity and reliability in commercial and industrial settings.

The construction of tray cables often includes a combination of copper or aluminum conductors, along with insulation types such as PVC, which are known for their resistance to heat and fire. A study conducted by the Institute for Electrical and Electronic Engineers (IEEE) highlights that tray cables can effectively function in temperatures ranging from -40°C to 90°C, making them a dependable choice for diverse applications, from manufacturing facilities to outdoor installations. Additionally, their ability to be installed in exposed locations and self-supporting systems allows for flexibility in design and installation, reducing the need for conduit which can further escalate project costs and complexity. This combination of features not only enhances performance but also contributes to cost-efficiency, making tray cables a strategic choice for modern electrical installations.

Cost Efficiency: Analyzing Long-Term Savings with Tray Cable Usage

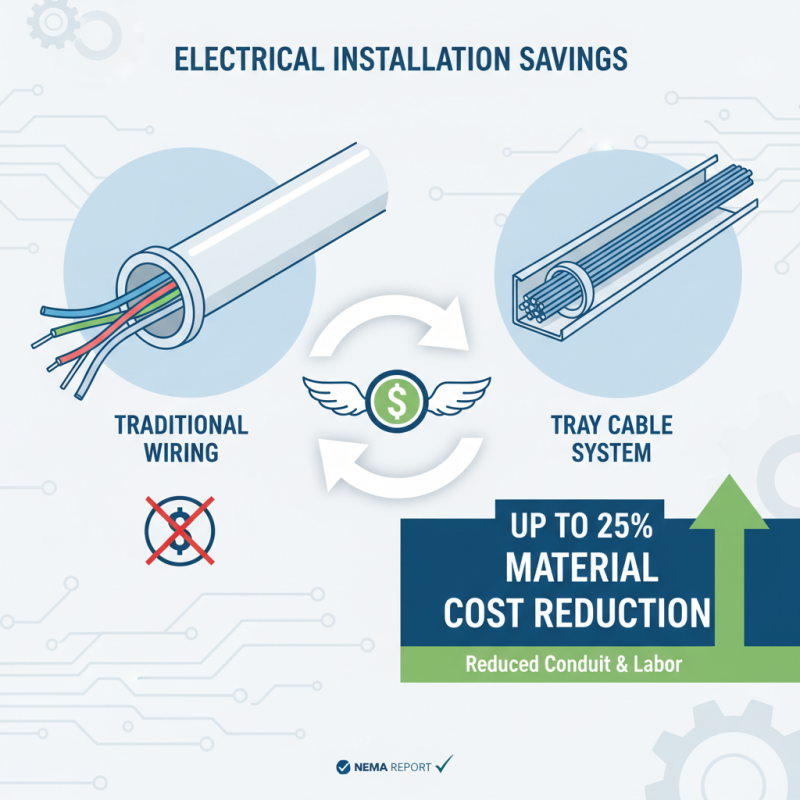

Tray cables have become increasingly popular in electrical installations due to their various cost-saving attributes. According to a report by the National Electrical Manufacturers Association, the installation of tray cables can reduce material expenses by up to 25% compared to traditional wiring methods. This significant reduction is primarily due to the simplified installation process and reduced need for conduit, which minimize both labor hours and material costs. As industries venture towards more budget-conscious practices, adopting tray cables not only enhances operational efficiency but also aligns with financial prudence.

Moreover, long-term savings associated with tray cable usage extend beyond initial installation costs. A study conducted by the International Electrotechnical Commission indicates that tray cables often lead to lower maintenance costs over their lifespan, thanks to their durability and resistance to environmental factors. In environments where cables are exposed to harsh conditions, tray cables exhibit a longer functional life, thus reducing replacement frequency and associated labor costs. This positions tray cables as a smart investment for facilities looking to optimize their operational expenses while maintaining high safety and performance standards in their electrical systems.

Versatility in Applications: Industries Benefitting from Tray Cables

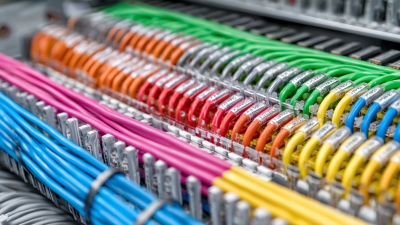

Tray cables have gained significant popularity across various industries due to their versatility and reliability in electrical installations. These cables are designed to be used in cable trays, making them ideal for environments where space is limited and organization is essential. Industries such as manufacturing, commercial construction, telecommunications, and entertainment systems are particularly benefitting from the adaptability of tray cables. Their ability to carry multiple conductors and support various connections without the need for individual conduits provides a streamlined solution for many electricians and engineers.

When considering tray cables for your next installation, it’s important to keep a few tips in mind. First, ensure that the chosen cable type matches the environmental conditions of your application—some are better suited for wet or hazardous locations due to added protective features. Second, pay attention to the cable’s rated voltage and ampacity to ensure it meets the demands of your specific project. Lastly, always follow local electrical codes and guidelines when installing tray cables to guarantee safety and compliance.

Tray cables not only enhance installation efficiency but also reduce labor costs associated with managing multiple wires. Their design allows for easier handling during installation, resulting in quicker project timelines. As industries continue to evolve, the demand for reliable and flexible electrical solutions will only increase, making tray cables an essential component of modern electrical systems.

Top Benefits of Using Tray Cables for Electrical Installations Today

Improved Safety Standards: Compliance and Risk Reduction with Tray Cables

Tray cables have become increasingly essential in electrical installations, particularly due to their enhanced safety features that align with modern safety standards. One of the primary benefits of using tray cables is their ability to minimize risks associated with electrical hazards. These cables are designed to be used in cable trays, which not only provide physical protection but also ensure that the cables remain organized and accessible. This setup significantly reduces the chances of accidental damage during installation or maintenance, promoting a safer working environment for technicians and operators.

Furthermore, tray cables adhere to stringent compliance regulations that address environmental and safety concerns. By containing materials that are less prone to combustion and providing excellent electrical performance, these cables help mitigate fire risks. Their robust construction allows them to withstand harsh conditions, making them suitable for a variety of applications in industrial, commercial, and residential settings. The compliance with safety standards afforded by these cables contributes to risk reduction, ensuring that installations meet required local and national codes. This focus on safety not only protects infrastructure but also enhances the overall reliability of electrical systems, promoting a culture of safety within the industry.

Conclusion

Tray cables are becoming increasingly popular in electrical installations due to their numerous advantages. One of the key benefits is their enhanced durability, which stems from their robust construction and high-quality materials, making them suitable for various environmental conditions. Additionally, tray cables offer cost efficiency by providing long-term savings, as they require less frequent replacement and maintenance compared to traditional wiring solutions.

Moreover, tray cables demonstrate versatility, being applicable across multiple industries, such as manufacturing, telecommunications, and construction. They also contribute to improved safety standards, ensuring compliance with regulations and reducing associated risks. Lastly, their design streamlines the installation and maintenance processes, ultimately simplifying electrical projects. Overall, the adoption of tray cables can significantly enhance both the performance and safety of electrical systems.

Related Posts

-

Understanding Cable Looms: The Essential Guide to Choosing the Right Wiring Solution for Your Projects

-

10 Essential Tips for Organizing Your Cable Loom Like a Pro

-

10 Essential Tips for Using THHN Wire in Your Electrical Projects

-

2025 Top Trends in Electrical Wire: Insights from the Global Market Report

-

How to Choose the Best Wire Puller for Your Electrical Projects

-

Top 10 THHN Wire Options for Your Electrical Projects in 2023