Top 10 Best THHN Wire Options for Electrical Wiring Projects

When it comes to electrical wiring projects, selecting the right materials is crucial for ensuring safety, efficiency, and longevity. Among the various wiring options available in the market, THHN wire stands out as a popular choice for professionals and DIY enthusiasts alike. THHN wire, which stands for Thermoplastic High Heat-resistant Nylon-coated wire, is designed to resist heat and moisture, making it ideal for a variety of applications including residential, commercial, and industrial settings. According to the National Electrical Manufacturers Association (NEMA), the use of proper wiring like THHN can significantly reduce the risk of electrical fires and improve the overall performance of electrical systems.

The demand for high-quality THHN wire has been on the rise, with market reports indicating a steady growth in the electrical wire and cable industry. A study by Grand View Research forecasts that the global wire and cable market is expected to reach $252.6 billion by 2025, highlighting the critical role of durable and reliable wiring solutions in modern infrastructure. As construction projects increasingly prioritize electrical safety and energy efficiency, THHN wire remains a top contender due to its excellent insulation properties and versatility.

In this guide, we will explore the top 10 best THHN wire options available, providing insights into their features, specifications, and suitable applications. By understanding the key attributes of each option, you'll be better equipped to make informed decisions for your electrical wiring projects, ensuring optimal performance and compliance with industry standards.

Understanding THHN Wire: Definition and Applications

THHN wire, which stands for Thermoplastic High Heat-resistant Nylon-coated wire, is a type of electrical wire commonly used in various wiring projects. Its construction features a solid or stranded copper or aluminum conductor, which is insulated with a combination of thermoplastic and nylon. This insulation provides excellent resistance to heat and moisture, making THHN wire suitable for both indoor and outdoor applications. It can be used in general electrical installations, such as in homes, commercial buildings, and industrial settings, where reliability and durability are paramount.

When working with THHN wire, it’s crucial to consider certain tips to ensure a successful installation. First, always check the wire’s ampacity rating to prevent overheating and potential hazards. Be mindful of the environment where the wire will be installed; while THHN wire is partially moisture-resistant, it should be housed in conduits when exposed to outdoor elements. Lastly, using the correct gauge wire based on the current load and distance of the run will help maintain efficiency and safety throughout your electrical project. These simple yet effective practices can significantly enhance the performance and longevity of your wiring work.

Top 10 Best THHN Wire Options for Electrical Wiring Projects

| Type | Gauge | Conductors | Insulation Type | Temperature Rating | Applications |

|---|---|---|---|---|---|

| THHN Copper | 10 | 1 | Thermoplastic (PVC) | 90°C (wet/dry) | Power distribution, branch circuits |

| THHN Aluminum | 6 | 1 | Thermoplastic (PVC) | 90°C (wet/dry) | Residential, commercial wiring |

| THHN Multi-Stranded | 12 | 7 | Thermoplastic (PVC) | 90°C (wet/dry) | Control circuits, motors |

| THHN Green | 14 | 1 | Thermoplastic (PVC) | 90°C (wet/dry) | Grounding applications |

| THHN Red | 8 | 1 | Thermoplastic (PVC) | 90°C (wet/dry) | Power applications, light circuits |

| THHN Blue | 10 | 1 | Thermoplastic (PVC) | 90°C (wet/dry) | Branch circuits, feeders |

| THHN Black | 4 | 1 | Thermoplastic (PVC) | 90°C (wet/dry) | Heavy machinery, high power applications |

| THHN Sheathed | 12 | 2 | Thermoplastic (PVC) | 90°C (wet/dry) | Flexibility in tight spaces |

| THHN Outdoor | 10 | 1 | Thermoplastic (PVC) | 90°C (wet/dry) | Outdoor installations, commercial |

Key Features of THHN Wire for Electrical Projects

When it comes to electrical wiring projects, selecting the right type of wire is crucial for safety and efficiency. THHN wire, known for its versatility and performance, is a prime choice among electricians and DIYers alike. One of its key features is its thermoplastic insulation, which provides excellent resistance to heat and moisture. This makes THHN wire suitable for both dry and wet locations, ensuring that your installations remain reliable over time.

Another important characteristic of THHN wire is its high tensile strength, allowing it to withstand physical stress without compromising its integrity. It is designed to support a variety of applications, from residential to industrial settings. Moreover, its copper core enhances conductivity, which is essential for minimizing energy loss and improving overall performance in electrical systems.

**Tips:** When working with THHN wire, ensure that you choose the appropriate gauge for your project's load requirements. Additionally, always strip the insulation with care to prevent damage to the wire, which can lead to safety hazards. Lastly, consider your installation environment to determine whether an additional protective conduit is necessary, especially in areas prone to adverse conditions.

Top 10 THHN Wire Brands: Overview and Comparisons

When it comes to selecting THHN wire for electrical wiring projects, understanding the brand options available is essential for ensuring reliability and performance. According to industry reports, the THHN wire market is projected to grow significantly, driven by rising demand in various sectors such as construction, manufacturing, and renewable energy. This growth is largely attributed to the outstanding electrical, thermal, and chemical properties of THHN wire, which make it suitable for a range of applications.

Various brands in the market offer different specifications of THHN wire, often characterized by their particular insulation materials and temperature ratings. A recent survey indicates that users frequently prioritize factors such as tensile strength, conductivity, and flexibility when choosing a brand. Comparative analyses have shown that wire produced with high-quality copper exhibits lower electrical resistance, contributing to energy efficiency and reduced operational costs. Additionally, the insulation types, typically nylon or PVC, play a vital role in determining the wire's longevity and adaptability in harsh environments.

Furthermore, expert evaluations reveal that customer satisfaction is closely aligned with the consistency of quality-control practices employed by the manufacturers. Many professionals recommend looking for brands that provide comprehensive testing data, compliance certifications, and durability guarantees, as these can greatly influence project success and safety. Investing in reliable THHN wire from reputable manufacturers can lead to enhanced performance and longevity in electrical wiring projects.

Factors to Consider When Choosing THHN Wire for Your Needs

When selecting THHN wire for electrical wiring projects, several crucial factors come into play. Firstly, the wire gauge is important; it determines the current-carrying capacity and influences the overall safety and performance of the installation. Thicker wires can handle higher loads, while thinner wires are suitable for lighter tasks. Always assess the specific electrical requirements of your project to ensure that you choose a gauge that meets the demands of your application.

Additionally, insulation type and environmental conditions are key considerations. THHN wire features nylon insulation that provides excellent resistance to heat, moisture, and chemicals, making it suitable for a variety of environments. However, if the wire will be exposed to extreme temperatures or harsh conditions, it may be necessary to look for specialized versions or additional protective measures. Furthermore, understanding the color coding of THHN wire is essential for proper identification during installation, which minimizes the risk of errors and enhances safety. By taking these factors into account, you can make an informed choice that ensures an efficient and reliable wiring project.

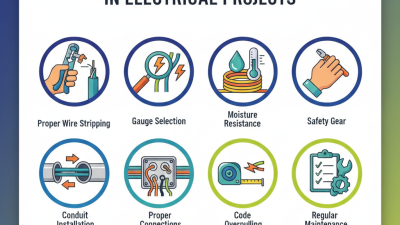

Installation Tips for Maximizing THHN Wire Performance

When working with THHN wire for electrical wiring projects, installation techniques play a crucial role in maximizing its performance. First and foremost, it's essential to ensure that the wire is installed correctly regarding the correct gauge and length for your specific needs. Properly stripping the insulation and securing the connections can prevent voltage drops and enhance overall efficiency. Always use the recommended tools for cutting and terminating the wire, as this helps maintain integrity and prevents damage to the copper conductor.

Additionally, considering environmental factors can significantly impact the longevity and effectiveness of THHN wire. When installing in harsh conditions, such as areas with high moisture or exposure to chemicals, using a protective conduit can shield the wire from potential degradation. It’s also advisable to follow the NEC (National Electrical Code) guidelines regarding temperature ratings and installation environments to ensure compliance and safety. Taking the time to carefully plan and execute the installation phase will lead to a more reliable and durable electrical system, which ultimately maximizes the performance of your THHN wire.

Related Posts

-

2025's Top 5 THHN Wire Innovations: Essential Choices for Electrical Projects

-

10 Essential Tips for Using THHN Wire in Your Electrical Projects

-

Top 10 THHN Wire Options for Your Electrical Projects in 2023

-

4 AWG THHN Wire Best Applications and Installation Tips You Need to Know

-

Why Wire Cable Tray Solutions Are Essential for Modern Electrical Systems

-

Top Trends in Wire Cable Tray Solutions for 2025 You Need to Know