2025 How to Choose the Best Multi Conductor Cable for Your Electrical Projects

In the evolving landscape of electrical engineering, selecting the right components for projects can significantly influence performance and efficiency. One critical element that stands out is the multi conductor cable, which is essential for a wide range of applications, from industrial setups to sophisticated audio systems. According to electrical industry expert John Smith, “Choosing the right multi conductor cable is not just about connectivity; it's about ensuring safety and optimizing signal integrity.” His insights underline the importance of understanding the specific requirements of a project before making a decision.

As the demand for reliable connectivity grows, so does the range of multi conductor cables available on the market. This makes it imperative for engineers and technicians to carefully evaluate their options. Factors such as conductor material, insulation type, and intended usage play crucial roles in determining which multi conductor cable will best suit a given application. By addressing these considerations, professionals can ensure that their electrical projects operate effectively and safely, while also minimizing the risk of costly failures or interruptions.

Understanding Multi Conductor Cable: Key Features and Functions

When selecting a multi conductor cable for your electrical projects, it’s essential to understand the key features and functions that distinguish these cables from standard options. Multi conductor cables consist of multiple insulated conductors bundled together, allowing for efficient transmission of multiple signals or power sources within a single cable. This design is particularly valuable in complex electrical systems, where space and organization are critical.

One of the most important aspects to consider is the gauge or thickness of the conductors, as this directly impacts the current-carrying capacity and voltage drop. Thicker conductors can handle higher currents without overheating, making them suitable for demanding applications. Additionally, the material used for insulation plays a significant role in determining the cable's durability and resistance to environmental factors such as moisture, chemicals, and temperature fluctuations. Understanding these features will help you choose the right multi conductor cable that meets the specific needs of your project while ensuring safety and efficiency in electrical systems.

2025 How to Choose the Best Multi Conductor Cable for Your Electrical Projects

| Feature | Description | Key Considerations | Applications |

|---|---|---|---|

| Conductor Material | Copper or aluminum conductors | Copper offers better conductivity, while aluminum is lighter and more cost-effective. | Power distribution, signal transmission |

| Number of Conductors | Varies from 2 to 37 or more | Choose based on your circuit requirements. | Instrumentation, control systems |

| Conductor Gauge | AWG ratings measure wire diameter | Larger gauges can carry more current. | Industrial machinery, HVAC systems |

| Insulation Type | PVC, XLPE, Teflon | Different types offer varying levels of heat resistance and flexibility. | Automotive, mining applications |

| Shielding Options | Foil, braided, or none | Shielding helps reduce electromagnetic interference (EMI). | Data cables, audio/video equipment |

| Temperature Rating | Range from -40°C to 90°C | Select a cable that can withstand the environmental conditions. | Outdoor installations, heavy machinery |

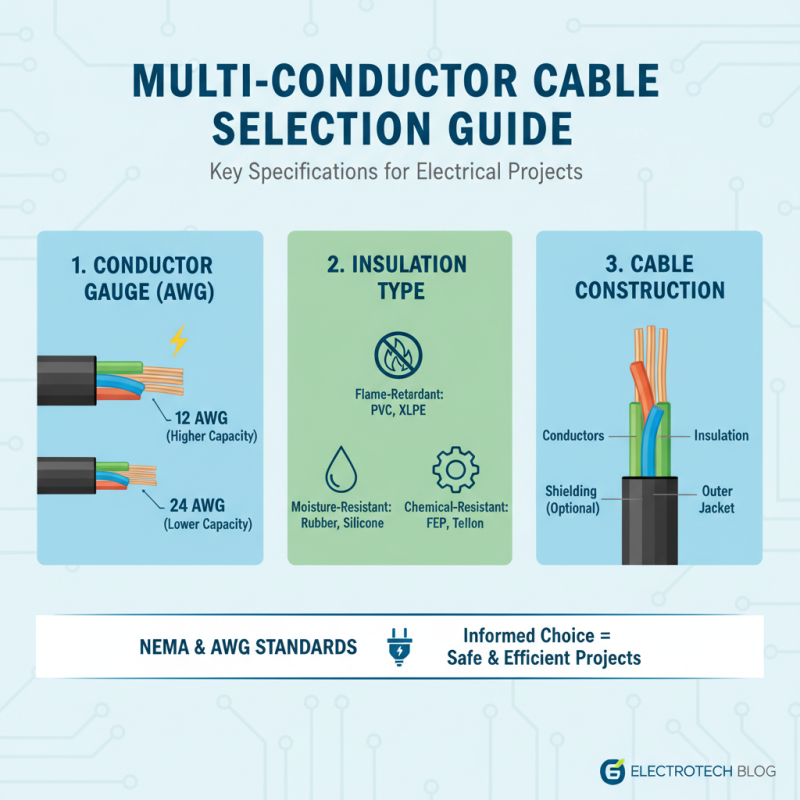

Identifying the Right Specifications for Your Electrical Projects

When embarking on electrical projects, selecting the right multi conductor cable is pivotal, and understanding the proper specifications is the first step in making an informed choice. According to the National Electrical Manufacturers Association (NEMA), multi conductor cables are highlighted for their versatility in applications ranging from industrial automation to residential wiring. The specifications you should consider include conductor gauge, insulation type, and overall cable construction. For instance, a lower gauge number indicates a thicker conductor and, typically, a higher current-carrying capacity. This is critical, especially for projects demanding high-power delivery without overheating, as indicated by the American Wire Gauge (AWG) standards.

Additionally, insulation type plays a significant role in cable performance and longevity. The International Electrotechnical Commission (IEC) has reported that certain insulation materials, such as PVC (Polyvinyl Chloride) and XLPE (Cross-Linked Polyethylene), have varying resistance levels to heat, chemicals, and environmental factors. For instance, XLPE cables, which feature a higher thermal rating, can operate efficiently in environments reaching up to 90°C. Consequently, selecting the appropriate insulation not only affects safety but also contributes to system efficiency and durability. By assessing these specifications, project managers can ensure that the multi conductor cables they choose can withstand the specific demands of their applications while adhering to applicable safety standards.

Comparing Different Types of Multi Conductor Cables Available

When choosing the right multi conductor cable for electrical projects, understanding the different types available is crucial. Multi conductor cables typically fall into three main categories: shielded, unshielded, and twisted pair. Shielded cables are widely recognized for their ability to minimize electromagnetic interference (EMI), making them ideal for environments with significant electromagnetic noise. According to a report from the International Electrotechnical Commission, shielding can reduce EMI by up to 95%, ensuring reliable performance for sensitive applications.

Unshielded multi conductor cables, on the other hand, offer greater flexibility and cost-effectiveness for less demanding environments. These cables are often used in applications where interference is minimal, providing a viable option for general wiring needs. A study by the National Electrical Manufacturers Association indicates that unshielded cables can be up to 30% lighter than their shielded counterparts, enhancing ease of installation without compromising functionality.

Twisted pair cables combine the advantages of shielding and proper twisting, making them suitable for versatile applications. This design significantly reduces crosstalk, according to research published by the Institute of Electrical and Electronics Engineers, achieving crosstalk reduction rates of over 50% in high-frequency scenarios. Assessing these characteristics—EMI resistance, flexibility, and crosstalk—will aid in selecting the most suitable multi conductor cable for your specific electrical project needs.

Evaluating the Importance of Cable Length and Gauge Selection

When selecting the best multi conductor cable for your electrical projects, understanding the significance of cable length and gauge is crucial. The cable length directly affects the overall performance of your electrical system. Longer cables can lead to signal loss and reduced efficiency, especially when carrying power or data over significant distances. This can result in subpar operating conditions for connected devices. Therefore, aim to minimize the length of wiring runs whenever possible, while ensuring that the cable is long enough to reach its endpoints comfortably.

On the other hand, gauge selection plays a vital role in determining the cable's capacity to carry current without overheating. A lower gauge number denotes a thicker wire, which can handle higher current loads more effectively. However, thicker cables can be more rigid and less flexible, making installation more challenging in tight spaces. It’s essential to balance the requirements of your project with appropriate gauge selection based on the electrical load and distance involved. By carefully evaluating both the length and gauge of the multi conductor cable, you ensure optimal performance, safety, and longevity of your electrical installations.

Tips for Proper Installation and Maintenance of Multi Conductor Cables

When working with multi conductor cables, proper installation is crucial to ensure both functionality and longevity. Begin by carefully planning your layout to prevent unnecessary bends or twists, which can compromise the integrity of the conductors. It's essential to use the right tools for the job, such as wire strippers and crimping tools, to prevent damage during installation. Ensure that the cables are not under excessive tension, as this can cause insulation breakdown over time. Additionally, pay attention to environmental factors such as temperature and exposure to chemicals, which can significantly impact the performance of the cables.

Regular maintenance is equally important to keep your multi conductor cables in optimal condition. Conduct periodic inspections to check for signs of wear, such as fraying or cracking of the insulation. Maintain a clean environment free from moisture and debris, which can lead to corrosion or short circuits. It's also wise to keep track of any connections or junction points, as these areas are often more susceptible to issues. By implementing these maintenance practices, you can ensure a reliable electrical system that effectively meets your project's needs.

Related Posts

-

2025's Top 5 THHN Wire Innovations: Essential Choices for Electrical Projects

-

What are Wire Zip Ties and How to Choose the Right One for Your Project

-

What is Alarm Cable? Understanding Types, Uses, and Installation Tips

-

Top 5 Benefits of Using High-Quality Cable Harnesses for Your Projects

-

How to Choose the Best Wire Puller for Your Electrical Projects

-

Why Wire Cable Tray Solutions Are Essential for Modern Electrical Systems