How to Choose the Right Fire Alarm Cable for Your Needs?

Selecting the right fire alarm cable is essential for ensuring safety and compliance in building projects. According to the National Fire Protection Association (NFPA), over 3,000 fires occur daily in the U.S., highlighting the need for reliable fire alarm systems. The correct type of fire alarm cable can significantly impact system performance and durability.

Industry expert John Smith, a leading consultant in fire safety technology, states, "Choosing the appropriate fire alarm cable is crucial. It can mean the difference between a swift response and potential disaster." When selecting fire alarm cables, factors like cable type, insulation rating, and fire resistance must be considered.

Many developers overlook these details, which could lead to dangerous outcomes. For instance, some may opt for lower-cost alternatives that compromise safety. It’s vital to balance budget constraints with the need for high-quality materials. Taking these steps can enhance safety and protect lives effectively.

Understanding Fire Alarm Cable Types and Their Applications

Choosing the right fire alarm cable is crucial for safety and compliance. Understanding the types available can help ensure you select the best option for your needs. There are various types of fire alarm cables, including FPL, FPLR, and FPLP. Each serves different applications and environments.

FPL cables are standard for general fire alarm systems. They are suitable for use in dry, protected locations. In contrast, FPLR cables are rated for riser applications. This means they can run vertically between floors, offering better fire resistance. The data indicates that over 60% of fire alarm failures are due to improper cabling.

Tips: Always check for voltage ratings and conductor sizes. This information ensures compatibility with your system.

For critical installations, consider using FPLP cables. These are plenum-rated, ideal for air-handling spaces. However, these cables can be more expensive. Balancing cost and safety is key.

Remember that installation techniques matter too. Properly securing cables prevents damage and maintains performance. Over time, wear and tear can lead to issues. Regular inspections are recommended to identify potential risks.

Evaluating Key Specifications for Fire Alarm Cables

When selecting a fire alarm cable, it's crucial to evaluate key specifications. The most important specifications include cable type, fire rating, and conductivity. According to the National Fire Protection Association (NFPA), using the correct fire-rated cable can significantly impact safety. For instance, low smoke zero halogen (LSZH) cables reduce toxicity and smoke in case of a fire.

Conductivity is another critical factor. Cables with higher conductivity ensure reliable signal transmission. A study from the Institute of Electrical and Electronics Engineers (IEEE) emphasized that using cables with minimum resistance can lead to better performance in emergencies.

Tips: Always check for certifications related to local fire codes. Make sure the cables you choose meet the standards outlined in the NFPA guidelines. Consider the environment where the cable will be installed. Indoor cables need different ratings than outdoor ones.

It's essential to visibly inspect cables for any visible damage or wear. Fire alarm systems depend on every component working correctly. Even minor imperfections can lead to major failures during critical moments. Remember, the wrong choice can compromise safety. Reflecting on what is truly needed is key to making the right decision.

How to Choose the Right Fire Alarm Cable for Your Needs?

| Specification | Description | Importance |

|---|---|---|

| Cable Type | Fire-resistant and low smoke cables | Essential for safety and compliance |

| Conductor Material | Copper vs. Aluminum | Affects conductivity and durability |

| Number of Conductors | Single vs. multi-core | Depends on the complexity of the fire alarm system |

| Cable Rating | Voltage and current capacity | Critical for performance and safety |

| Insulation Material | PVC, LSZH, etc. | Influences fire performance and health risks |

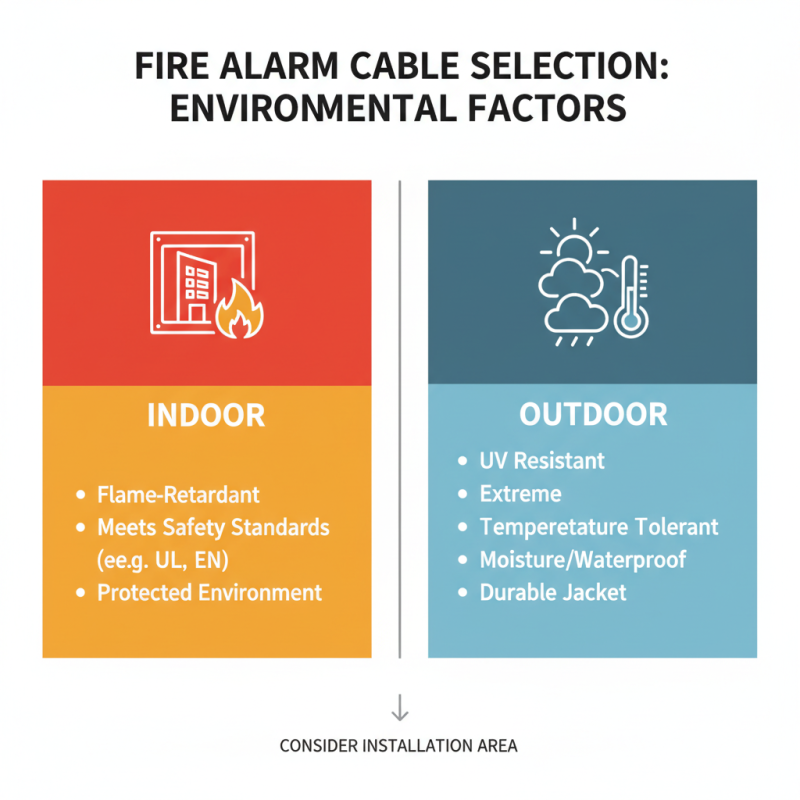

Assessing Environmental Considerations for Fire Alarm Cable Selection

When selecting a fire alarm cable, environmental factors play a crucial role. Consider the installation area. Is it an indoor or outdoor environment? Outdoor cables need to withstand UV rays and extreme temperatures. Indoor cables should be flame-retardant and meet safety standards.

Make sure to assess the humidity levels too. High moisture can lead to corrosion. In areas with high humidity, choose cables with moisture-resistant coatings. This enhances durability and reduces maintenance issues in the long run.

Tips: For outdoor installations, check for cables rated for wet conditions. Indoor installations might require low smoke and halogen-free options. Regularly inspect cable insulation for wear. Understanding your environment ensures safety and reliability in fire alarm systems.

Determining Installation Requirements for Fire Alarm Cables

When determining installation requirements for fire alarm cables, several factors come into play. First, you need to evaluate the environment where the cables will be installed. This includes understanding the temperature, humidity, and potential exposure to chemicals. High-temperature areas might require specific insulation. Humid environments may need moisture-resistant cables.

It's essential to assess the distance between the fire alarm system and the detectors. Longer distances might require thicker cables to maintain signal integrity. If you are installing cables through walls, consider using conduit for protection. Many installations overlook this step, which can lead to deterioration over time.

Tips: Check local codes for any specific regulations regarding cable installation. Ensure that the chosen cable type can withstand environmental challenges. Testing the cable after installation is crucial. A faulty connection could compromise safety. Always document your installation process for future reference. This could help identify any issues later.

Comparing Cost and Quality for Optimal Fire Alarm Cable Choices

When choosing fire alarm cables, cost and quality are crucial. High-quality cables offer better durability and reliability. Cheaper options may save money upfront, but they often fall short in performance. Think about the long-term implications. A faulty cable can lead to serious consequences.

Consider the installation environment. Cables should withstand moisture, heat, and other factors. An outdoor installation, for example, requires a different specification than indoor use. The right choice can affect your system's effectiveness.

Tips: Always check for certifications. This ensures that the cable meets safety standards. Additionally, ask for samples, if possible. Testing a small section can reveal insights about performance. Also, evaluate warranty options. A trustworthy warranty reflects the manufacturer’s confidence in their product. Don't rush your decision; it’s essential to weigh all factors carefully.

Related Posts

-

2025 Top 10 Stranded Wire Options for Electrical Projects: Expert Insights and Industry Trends

-

2025 Guide: How to Choose the Right Wire Tray for Your Projects

-

Understanding the Essentials of Wiring Looms: A Guide to Simplifying Your Projects

-

Top 5 Wire Zip Ties to Enhance Your Organization and DIY Projects in 2025

-

Top Benefits of Using Tray Cables for Electrical Installations Today

-

Mastering Cable Pulling Tools: Essential Techniques for Efficient Installation and Maintenance