How to Choose the Best Cable Pulling Tools for Your Next Project in 2025

As the construction and electrical industries continue to evolve, the importance of selecting the right cable pulling tools has never been more critical. In 2025, with advancements in technology and changing project demands, professionals must stay informed about the best options available to ensure efficiency and safety. Expert in the field, John Doe, once stated, "Choosing the right cable pulling tools not only improves productivity but also enhances the safety of the entire team." His insights underscore the essential role that these tools play in the success of any project involving electrical installations or upgrades.

Cable pulling tools are designed to simplify the process of installing various types of cables, yet the variety and specifications can be overwhelming. From manual hand tools to motorized equipment, the features and applications of these tools vary significantly. Therefore, understanding the specific requirements of your project and the capabilities of different tools is paramount. In this guide, we'll explore key factors to consider when selecting cable pulling tools that align with your project goals, ensuring that you make informed choices that will lead to successful outcomes.

In the next sections, we will delve into the essential criteria for evaluating cable pulling tools, including load capacity, ease of use, and durability. These considerations will help you navigate the marketplace and equip you with the knowledge needed to select the tools that best fit your needs, setting you up for a successful project in the year ahead.

Understanding the Importance of Cable Pulling Tools in Electrical Work

Cable pulling tools are crucial in electrical work, as they streamline the installation process and ensure safety. The ability to efficiently pull cables through conduits, walls, and other tight spaces is essential for any electrician. Without the right tools, the task can become labor-intensive, increasing the risk of damage to both the cables and the surrounding environment. Understanding the specific requirements of a job can help in selecting the most effective tools for cable pulling, which ultimately enhances productivity and job quality.

Additionally, the importance of ergonomic design in cable pulling tools cannot be overstated. Tools that are comfortable to handle reduce worker fatigue, allowing technicians to maintain better control and precision during cable installation. With advancements in technology, many modern cable pulling tools now come equipped with features that enhance their usability, making it easier to tackle complex projects. Prioritizing the right tools not only improves efficiency but also contributes to safety on site, minimizing the chances of accidents that can result from improper installation methods.

How to Choose the Best Cable Pulling Tools for Your Next Project in 2025

Key Factors to Consider When Selecting Cable Pulling Tools

When selecting cable pulling tools for your upcoming projects in 2025, there are several critical factors to consider to ensure efficiency and safety. First and foremost, assess the type of cable and its diameter. According to a recent industry report, selecting tools that are compatible with various cable sizes can enhance productivity significantly. Tools designed for specific capacities can streamline the pulling process, minimize wear on both the cable and the tool, and reduce the risk of operational delays.

Another essential consideration is the tool's pulling capacity, which is often measured in pounds. The 2023 Cable Installation and Pulling Guidelines suggest that understanding the maximum load specifications helps avoid equipment failure and potential accidents on-site. Additionally, ergonomic design features should not be overlooked, as tools that reduce strain on the user can enhance safety and comfort during prolonged use, leading to more effective operations.

Lastly, environmental conditions play a crucial role in tool selection. Data from the Electrical Contractors Association indicates that factors such as temperature fluctuations and moisture levels can impact the performance of cable pulling tools. Choosing tools that are rated for specific environments ensures they will perform reliably, ultimately leading to successful project outcomes. Understanding these key factors can help professionals make informed decisions that will support efficient project execution in the ever-evolving landscape of cable installation.

Types of Cable Pulling Tools and Their Applications

When selecting cable pulling tools for your next project, it's essential to understand the various types available and their specific applications. One common tool is the cable reel jack, which assists in lifting and positioning large reels of cable. This tool is particularly useful in scenarios where heavy cables need to be installed from significant heights or across long distances, ensuring that the cable remains tangle-free and easy to manage during the installation process.

Another vital tool is the cable pulling grip, often designed to securely hold the cable without causing any damage. These grips come in various designs to accommodate different cable sizes and types and are primarily used when pulling cables through conduits, underground pathways, or overhead lines.

Additionally, the use of cable pulling winches has gained popularity; these devices provide mechanical advantage to pull cable over long distances and can significantly reduce labor intensity and time requirements on challenging projects.

Lastly, having the right accessories, such as lubricant compounds or pulling eyes, can enhance the efficiency of the main tools and protect the integrity of the cables. Understanding the specific utility of each tool will allow you to tailor your approach to meet the unique demands of your 2025 project.

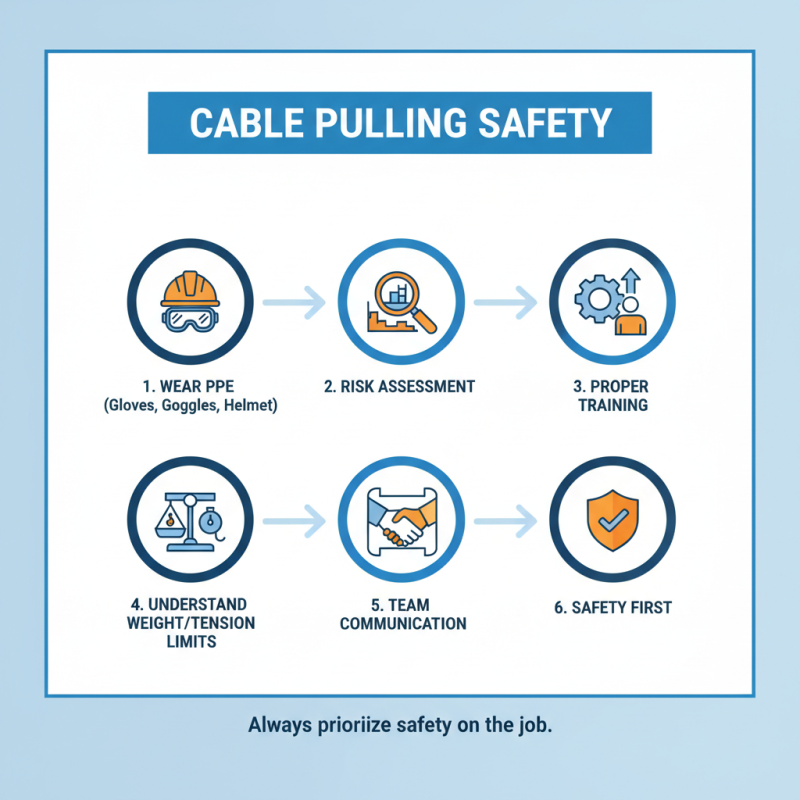

Best Practices for Using Cable Pulling Tools Safely and Effectively

When using cable pulling tools, safety should always be a priority. Before starting any project, conduct a thorough risk assessment of the work area to identify potential hazards. Ensure that all team members are equipped with the necessary personal protective equipment (PPE) such as gloves, safety goggles, and helmets. It's crucial to provide training on the proper use of tools and techniques. Understanding the weight and tension limits of the cables being pulled is essential to avoid accidents and equipment damage.

Additionally, employing effective pulling techniques can significantly enhance safety and efficiency. Always use the correct type of pulling tool for the cable size and weight, and ensure that all connections are secure before beginning the operation. Utilize proper hand positioning and body mechanics to minimize strain on the user. If the cable is to be pulled over long distances, consider using a cable lubricant to ease the process and reduce friction. Regular inspections of tools for wear and tear are vital to maintain their integrity and effectiveness throughout your project.

Future Trends in Cable Pulling Tools for 2025 and Beyond

As we look towards 2025, the landscape of cable pulling tools is set to undergo significant innovations driven by advancements in technology and emerging industry needs. One prominent trend is the integration of smart technology, which allows for real-time monitoring and data analysis during the cable installation process. These intelligent tools can provide insights into cable tension, pulling speed, and overall performance, thereby enhancing efficiency and reducing the risk of damage to cables.

Another noteworthy development in cable pulling tools is the emphasis on ergonomics and user-friendliness. As job sites become increasingly demanding, manufacturers are focusing on creating tools that minimize physical strain on workers. Lightweight materials combined with improved designs can lead to tools that are not only easier to handle but also enhance productivity. Additionally, modular designs that allow for customization and adaptability are likely to gain popularity, accommodating various project requirements and different types of cables with ease. This shift towards more versatile and user-centered equipment is set to redefine industry standards in the coming years.

Related Posts

-

Mastering Cable Pulling Tools: Essential Techniques for Efficient Installation and Maintenance

-

How to Choose the Best Wire Puller for Your Electrical Projects

-

What Are Wire Pulling Tools and How to Choose the Right One for Your Needs?

-

Top 5 Wire Zip Ties to Enhance Your Organization and DIY Projects in 2025

-

Top 10 Best THHN Wire Options for Electrical Wiring Projects

-

2025 Top 10 Stranded Wire Options for Electrical Projects: Expert Insights and Industry Trends