How to Use a Fish Tape Wire Puller Efficiently for Your Electrical Projects

In the world of electrical work, efficiency and precision are paramount, especially when it comes to running wires through walls and conduit. The use of a fish tape wire puller has become a staple for professionals and DIY enthusiasts alike. According to John Smith, a seasoned electrician with over 20 years of experience, "Mastering the use of a fish tape wire puller can significantly reduce the time and frustration involved in wiring projects." This statement underscores the importance of utilizing the right tools and techniques to enhance productivity.

The fish tape wire puller, a simple yet effective tool, allows users to easily navigate through tight spaces and pull wires with minimal hassle. Whether installing new lighting fixtures, setting up home networks, or addressing complex electrical systems, understanding how to deploy a fish tape wire puller efficiently can make a substantial difference in both results and overall job satisfaction. By combining expert techniques and the right equipment, electricians can not only improve their work quality but also streamline the wiring process, ensuring safety and compliance with industry standards.

Understanding Fish Tape and Its Importance in Electrical Work

Fish tape is an essential tool in the electrical trades, aiding professionals in the efficient installation of wiring through tight spaces. This flexible, elongated wire allows electricians to navigate through complex conduit systems, making it possible to pull multiple wires simultaneously. According to a report by the National Electrical Contractors Association (NECA), approximately 30% of electrical work delays can be attributed to inefficient wire pulling processes. Utilizing fish tape not only minimizes these delays but also enhances safety by reducing the physical strain on electricians.

Understanding the significance of fish tape extends beyond mere convenience; it significantly impacts project timelines and overall efficiency. Studies indicate that projects employing fish tape for wire installation can save up to 50% of the time typically spent on manual wire pulling. Additionally, the use of fish tape increases the lifespan of the wiring by preventing undue stress during pulls, ultimately leading to fewer service calls and repairs. As the demand for faster and more efficient electrical installations grows, mastering the use of fish tape becomes increasingly vital for professionals aiming to stay competitive in the market.

Choosing the Right Fish Tape Wire Puller for Your Project Needs

When choosing the right fish tape wire puller for your electrical projects, it is crucial to consider the specific requirements of each job. Fish tapes come in various materials, sizes, and strengths, each tailored for different applications. According to a report by the National Electrical Contractors Association (NECA), selecting the appropriate fish tape can significantly impact the efficiency and safety of wire installations. For instance, fiberglass fish tapes, known for their durability and flexibility, are excellent for navigating through tight bends and obstacles, making them ideal for residential wiring projects.

In addition, the length of the fish tape is a key factor to consider. A study by the Electric Power Research Institute (EPRI) found that using the correct tape length can reduce the time spent on pulling wires by up to 30%. Therefore, understanding the layout of the conduits and anticipated distances will guide electricians in selecting a fish tape that minimizes effort and maximizes productivity. Furthermore, the pull strength—often measured in pounds—is vital, especially when working with larger gauge wires. Ensuring that the fish tape can handle the required pull force can help maintain the integrity of both the wiring and the conduit system. By carefully evaluating these factors, electricians can choose a fish tape wire puller that enhances overall project efficiency.

Fish Tape Wire Puller Efficiency in Electrical Projects

Step-by-Step Guide to Using a Fish Tape Wire Puller Effectively

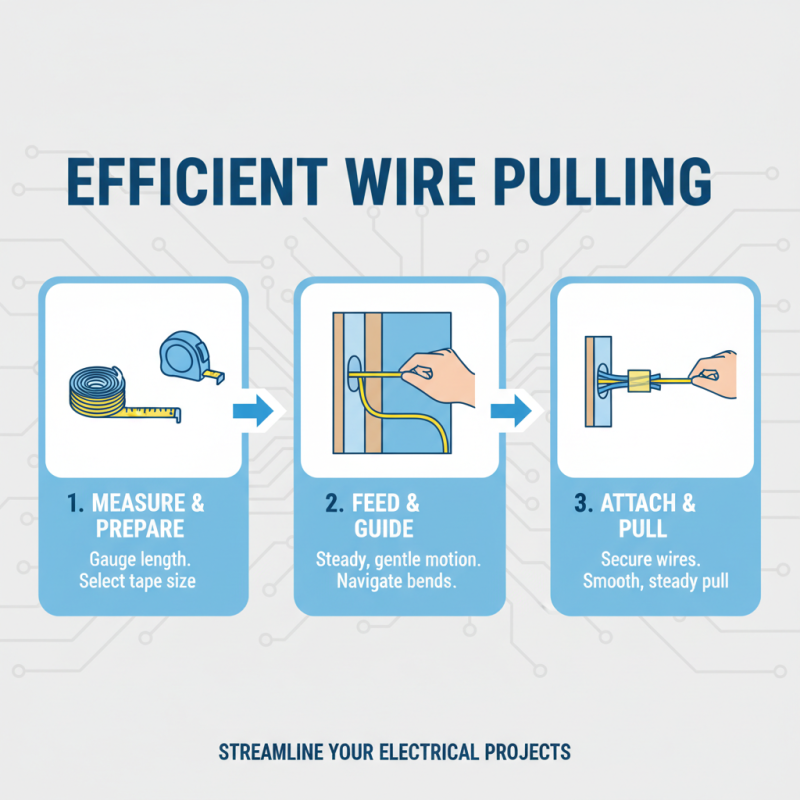

Using a fish tape wire puller can significantly streamline your electrical projects, ensuring wires can be efficiently threaded through walls, conduits, or ceilings. Start by measuring the length of the run you need to accomplish, so you can use an appropriately sized fish tape. Begin by feeding the fish tape into the access point. It’s essential to maintain a steady and gentle motion, allowing the tape to navigate bends and turns in the pathway without excessive force, which could cause the tape to jam or break.

Once the fish tape has been fed through, attach the wire securely to the fish tape’s end using electrical tape. Ensure the connection is firm and streamlined to avoid any snags while pulling the wire back through. Slowly pull the fish tape back, guiding it carefully to prevent any potential kinks or tangles. If resistance is encountered, stop and assess the situation rather than forcing the tape, as this could result in damage. With these steps followed, you can effectively use a fish tape wire puller for efficient electrical installations.

Best Practices for Maintaining and Storing Your Fish Tape

Proper maintenance and storage of your fish tape wire puller are crucial for ensuring its longevity and efficiency during electrical projects. After each use, it is important to clean the fish tape thoroughly. Remove any dirt, dust, or debris that may have accumulated during the pulling process. Inspect the tape for any signs of wear or damage, such as kinks or frays, as these issues can affect its performance. A lightly lubricated cloth can help maintain the tape’s smooth operation and minimize friction when using it next.

When it comes to storage, keeping your fish tape in a dry, secure location is vital. Avoid areas prone to moisture, as humidity can cause corrosion and weaken the tape over time. If your fish tape comes with a protective case or reel, make use of it; this helps prevent tangling and damage while providing an organized way to store the tool. Additionally, keeping the fish tape neatly coiled will prevent it from developing memory, which can lead to reduced effectiveness in future tasks. Adhering to these best practices will not only extend the life of your fish tape wire puller but also enhance your efficiency in upcoming electrical projects.

How to Use a Fish Tape Wire Puller Efficiently for Your Electrical Projects - Best Practices for Maintaining and Storing Your Fish Tape

| Best Practices | Description | Maintenance Tips | Storage Recommendations |

|---|---|---|---|

| Choose the Right Length | Select a fish tape that is long enough for your project, considering the distance of the run. | Clean the tape after use to remove dirt and dust. | Store in a dry area to avoid rusting. |

| Feed Tape Straight | Ensure the tape is fed straight into the conduit to prevent kinks and tangles. | Regularly inspect for any signs of wear or damage. | Use a storage reel for easy access and to avoid knots. |

| Use Proper Tools | Utilize a drill or an appropriate pulling tool to assist in navigating bends. | Lubricate the fish tape if necessary to reduce friction. | Avoid storing in extreme temperatures. |

| Practice Safety | Wear appropriate safety gear and check for live wires before pulling tape. | Keep fish tape away from moisture to prevent corrosion. | Store in a cool, shaded area protected from the elements. |

Common Mistakes to Avoid When Using a Fish Tape Wire Puller

When using a fish tape wire puller, avoiding common mistakes can greatly enhance the efficiency and safety of your electrical projects. One prevalent error is using the wrong type of fish tape for the job; ensure that you select a fish tape that is appropriate for the size and length of wires you need to pull. For example, choosing a wider, more rigid tape might be necessary for larger gauges, while a thinner, more flexible tape can work better in tight spaces. Always assess the environment and choose your tools wisely to optimize the pulling process.

Another common mistake is not preparing the pulling path adequately. Failing to clear debris or obstacles from the conduit can result in unnecessary friction or snags, which can damage the wires or the fish tape itself. Additionally, neglecting to lubricate the wires or the fish tape can lead to difficulty during the pulling process. Taking a moment to plan the route and ensure everything is clear and lubricated can save significant time and frustration down the line. By remaining vigilant and attentive to these common pitfalls, you can significantly improve the overall success of your wire-pulling tasks.

Related Posts

-

Top 5 Benefits of Using High-Quality Cable Harnesses for Your Projects

-

How to Use Wire Ties Effectively for Organizing and Securing Items

-

10 Essential Tips for Organizing Your Cable Loom Like a Pro

-

What is Building Wire? Understanding Types, Applications, and Industry Standards with Insights on 2023 Trends

-

Why Wire Cable Tray Solutions Are Essential for Modern Electrical Systems

-

2025 Guide: How to Choose the Right Wire Tray for Your Projects