Top Types of Building Wire for Your Electrical Needs?

When discussing electrical needs, understanding building wire choices is crucial. In the electrical industry, building wire is a fundamental component. It ensures safety and efficiency in residential and commercial installations. According to the National Electrical Manufacturers Association (NEMA), over 80% of electrical failures are linked to poor wiring choices.

Selecting the right type of building wire affects performance and durability. For example, copper wire remains a popular option due to its excellent conductivity and longevity. Aluminum wire, while lighter and often cheaper, presents some challenges. Its tendency to expand and contract can lead to connections loosening over time. This is a concern that needs attention.

Moreover, the American Wire Gauge (AWG) system can be confusing. Many builders may struggle with the correct gauge needed for their specific projects. Misjudging wire sizes could result in insufficient power delivery or even hazards. Reflecting on these choices is essential for both safety and functionality. Opting for the right building wire ultimately contributes to the success of an electrical project.

Overview of Different Types of Building Wire for Electrical Systems

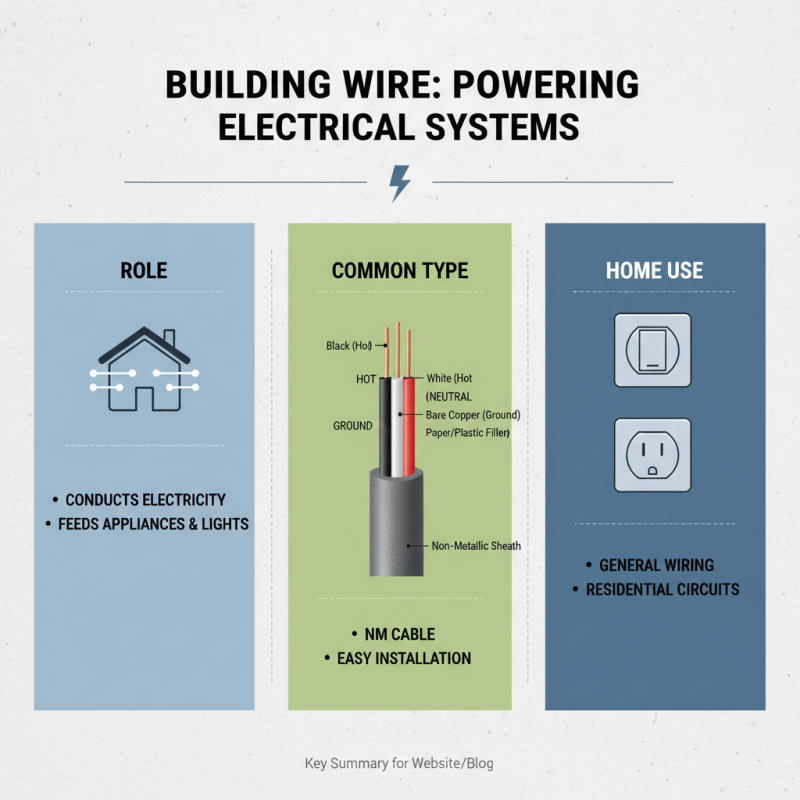

Building wire plays a crucial role in electrical systems. There are several types available, each serving different needs. One common choice is non-metallic sheathed cable. This type is easy to install. It typically contains two or three insulated wires and a ground wire. It's suitable for general wiring in homes.

Another option is Romex wire, which is versatile for residential use. This type combines both the insulated conductors and a grounding wire in a single sheathing. It's often found in dry locations. Beware, though; it’s not ideal for outdoor projects. Make sure to check the local codes before using it.

Then there’s underground feeder (UF) wire. This type is designed for outdoor use and can be buried without conduit. It's moisture-resistant and durable, making it a solid choice for landscape lighting. However, be cautious about depth requirements for burial. Installation mistakes can lead to issues. Always plan thoroughly before beginning any project.

Copper vs. Aluminum Wire: Strengths and Applications in Construction

When choosing electrical wiring, copper and aluminum are the top contenders. Copper wire is renowned for its excellent conductivity. It has lower resistance, which means less energy loss. According to the Institute of Electrical and Electronics Engineers (IEEE), copper provides around 60% more conductivity than aluminum. This makes copper ideal for high-load applications like commercial buildings.

On the other hand, aluminum wire offers significant advantages in terms of weight and cost. It is lighter and cheaper than copper. For instance, aluminum wire can be 50% less expensive per pound. However, users must consider the increased risk of oxidation. This can lead to poor connections and overheating if not managed properly. The National Electrical Code (NEC) outlines specific practices for aluminum wiring to mitigate these risks.

Ultimately, both materials have strengths and weaknesses. Copper excels in conductivity but comes with a higher price tag. Aluminum is budget-friendly, yet it risks connectivity issues if not installed correctly. Understanding these factors is crucial for making informed decisions in construction projects. Balancing cost, safety, and efficiency is key.

Understanding Wire Gauge: Importance in Electrical Load Capacity

When it comes to electrical systems, understanding wire gauge is crucial. A wire's gauge determines its ability to carry electrical current. This is essential for preventing overheating and ensuring efficiency. For example, a 12-gauge wire can handle up to 20 amps of current, while a 14-gauge wire is suitable for up to 15 amps. These differences can impact your home's electrical safety and performance.

Using the right gauge is often overlooked. Many homeowners may underestimate their needs. A common mistake is using too small a wire for a high-load application. This can lead to wire failure. Reports indicate that improper wiring is a key factor in electrical fires. According to the National Fire Protection Association, nearly 50% of electrical fires involve faulty wiring, underscoring the need for careful selection.

In addition, it’s vital to consider the length of wire run. Longer distances require larger gauges to reduce voltage drop. For instance, a wire run of over 100 feet may need to increase a gauge size to maintain efficiency. As a rule of thumb, closer distances allow for smaller gauges. However, not all projects are straightforward, and deviations often occur, leading to potential issues down the line.

Insulation Types: Selection Based on Environment and Safety Standards

When choosing building wire, insulation type is crucial. Different environments demand specific materials for optimal performance. For instance, in damp areas, moisture-resistant insulation is essential. This helps prevent electrical failures. In dry environments, standard insulation may suffice. However, using the wrong insulation can make wires less effective.

Tips: Always assess the environment before selecting wire. Consider temperature extremes, exposure to chemicals, and moisture levels. These factors directly impact wire longevity. Furthermore, adhere to safety standards. Ignoring them could lead to hazards.

Some wires come with ratings for fire resistance. This is important in high-temperature areas. Meanwhile, low-temperature-rated wires can be necessary for colder climates. Choosing based on these criteria ensures safety. It might be tempting to cut costs with cheaper insulation. However, this can lead to higher risks of malfunction and damage. Always prioritize quality over price.

Code Compliance: How to Ensure Your Wire Meets National Electrical Codes

When selecting building wire, compliance with the National Electrical Code (NEC) is essential. This ensures safety and functionality in electrical installations. Review the NEC guidelines often. New updates can lead to changes in requirements. A wire may look suitable but fail to meet code due to improper ratings or insulation types.

Consider wire types based on the application. For instance, NM (non-metallic) cables are common in residential projects, but may not be ideal for all situations. Environmental factors play a significant role too. Outdoor installations need wire with superior weather resistance. Additionally, with multi-family buildings, specific requirements apply. Ignoring these can result in costly mistakes.

It's crucial to check local amendments to the NEC. These can differ significantly from one area to another. A wire that fulfills requirements in one state may not in another. Always consult with a knowledgeable electrician. They can provide insights on best practices and potential pitfalls. Regularly revisiting code resources fosters better understanding, preventing oversights.

Related Posts

-

What is Building Wire? Understanding Types, Applications, and Industry Standards with Insights on 2023 Trends

-

How to Use a Fish Tape Wire Puller Efficiently for Your Electrical Projects

-

Why Wire Cable Tray Solutions Are Essential for Modern Electrical Systems

-

Understanding Cable Looms: The Essential Guide to Choosing the Right Wiring Solution for Your Projects

-

2025 Top Trends in Electrical Wire: Insights from the Global Market Report

-

10 Essential Tips for Organizing Your Cable Loom Like a Pro