What Are Wire Pulling Tools and How to Choose the Right One for Your Needs?

Wire pulling tools are essential instruments in the electrical and telecommunications industries, facilitating the smooth installation of wiring systems. As per the latest industry reports, the global wire and cable market was valued at approximately $210 billion in 2021 and is projected to reach around $300 billion by 2027, highlighting the increasing demand for efficient wiring solutions. This surge in growth emphasizes the importance of selecting the right wire pulling tools, as improper tools can lead to installation inefficiencies, increased labor costs, and potential damage to the wiring.

When choosing the optimal wire pulling tools, professionals must consider a range of factors, including wire gauge, installation environment, and the specific type of cables being used. Research indicates that the need for specialized tools has grown, with over 60% of electrical contractors adopting advanced wire pulling techniques to meet project demands more effectively. Whether tasked with running cables through conduits or pulling wires across long distances, understanding the variety and functionality of wire pulling tools is crucial. This guide aims to empower industry professionals with the knowledge to make informed choices tailored to their specific requirements, ensuring streamlined operations and enhanced performance.

Definition and Types of Wire Pulling Tools

Wire pulling tools are essential instruments used in various electrical and telecommunication applications. They facilitate the process of pulling wires through conduits or walls, ensuring smooth installation and minimizing damage to the wires. Among the most common types of wire pulling tools are fish tapes, wire pullers, and cable lubricants. Fish tapes are long, flexible tools that allow electricians to easily navigate tight spaces and guide wires through conduits. Wire pullers, on the other hand, provide mechanical assistance to pull heavier cables and are particularly useful for larger installations, making the task more efficient and less labor-intensive.

When choosing the right wire pulling tool, consider the specific requirements of your project. For instance, the diameter of the wires, length of the conduit, and the total weight of the cable play crucial roles in your selection process. Additionally, the environment in which the tool will be used is important; some tools are designed for indoor use, while others are built to withstand harsh outdoor conditions. Understanding the different types of wire pulling tools and their applications will help ensure that you select the most effective solution for your electrical needs, leading to safer and more reliable installations.

Key Features to Consider When Selecting Wire Pulling Tools

When selecting wire pulling tools, it is essential to consider several key features that can significantly impact their efficiency and effectiveness. Firstly, the type of wire or cable being pulled is crucial in determining the right tool. Different cables, such as fiber optic, low-voltage, or high-voltage wires, require various tools designed to handle their unique properties. According to the National Electrical Contractors Association (NECA), using the correct tool can enhance productivity by up to 30%, which emphasizes the importance of making the right choice.

Another important aspect is the tool's capacity and strength. Wire pulling tools come in various sizes and load ratings, with some capable of pulling loads exceeding 5,000 pounds. A report from the Electrical Safety Foundation International (ESFI) highlights that using adequately rated tools can prevent accidents and failures during installation, thereby reducing downtime and maintenance costs. Additionally, consider the ergonomics and weight of the tool; lightweight and well-designed tools minimize user fatigue, especially during long jobs. Research indicates that ergonomic tools can lead to a 20% decrease in work-related injuries, showcasing how the proper selection can enhance safety and comfort for workers on the job site.

Finally, the ease of use and versatility of the wire pulling tools should not be overlooked. Tools with multiple functionalities can save time and resources, allowing electricians to adapt to various job site demands. As electric systems become more complex, having versatile tools becomes increasingly valuable, ensuring that professionals can efficiently meet the growing industry needs.

What Are Wire Pulling Tools and How to Choose the Right One for Your Needs?

| Tool Type | Key Features | Ideal Use Case | Price Range |

|---|---|---|---|

| Fish Tape | Flexible, Lightweight, Easy to Handle | Pulling wire through conduits | $10 - $50 |

| Pulling Grips | Strong, Adjustable, Different Sizes | Heavy gauge wire and cables | $15 - $100 |

| Cable Pulling Machine | Electric, High Torque, Variable Speed | Long distances and heavy cables | $500 - $3,000 |

| Kite String | Lightweight, Cost-effective | For smaller wire pulls | $5 - $20 |

| Cable Lubricant | Reduces Friction, Non-toxic | Facilitating smoother pulls | $10 - $30 |

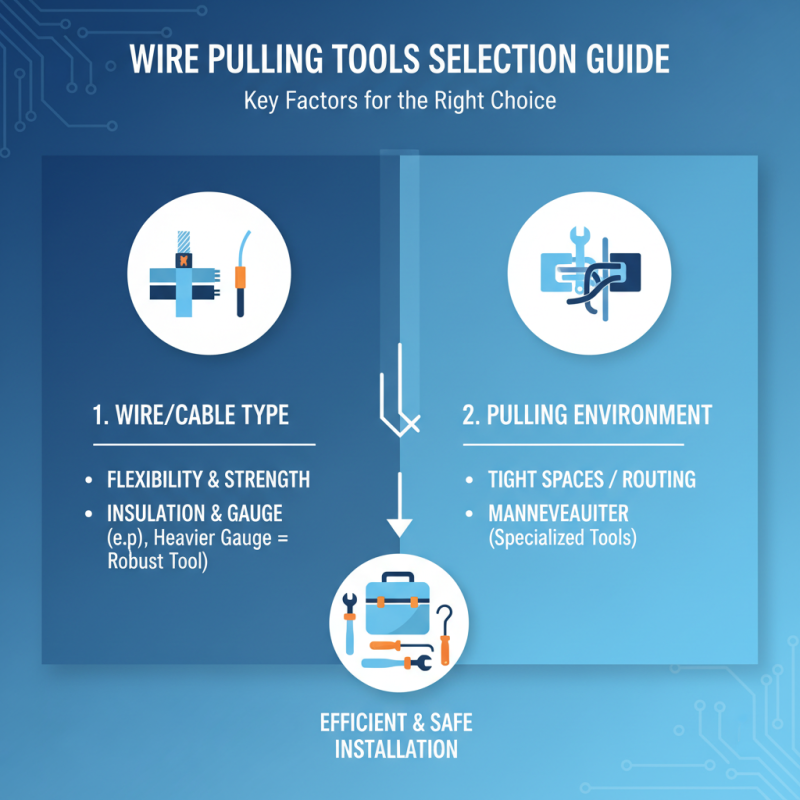

Factors Influencing the Choice of Wire Pulling Tools

When selecting wire pulling tools, several factors play a crucial role in ensuring you make the right choice for your specific needs. First, consider the type of wire or cable to be pulled. Different cables have varying levels of flexibility, strength, and insulation, which can influence the type of tool required. For example, heavier gauge wires may necessitate a more robust tool, while lighter cables could be managed with simpler devices. Additionally, assessing the environment where the wire will be pulled is essential. Tight spaces or complex routing may require specialized tools designed for maneuverability.

Tips: Always check the maximum pulling capacity of the tool you are considering. Ensure it exceeds the weight of the wire or cable to avoid potential tool failure during use. Furthermore, look for features such as ergonomic handles, which can significantly reduce fatigue during prolonged operations.

Another important factor is the length of the pull. Longer pulls might require tools that can effectively manage friction and avoid snags, which can damage the wire. Tools with built-in lubricating systems or those designed to reduce friction can be beneficial. Finally, think about the frequency of use and the investment you are willing to make. For occasional projects, renting may be a more economical choice, while regular use may justify purchasing higher-quality tools designed for durability and efficiency.

Common Applications of Wire Pulling Tools in Various Industries

Wire pulling tools are essential in various industries for the efficient installation of electrical wires, cables, and fibers. In telecommunications, for instance, the increasing demand for faster internet speeds has driven the market for wire pulling tools, particularly in the deployment of fiber optic cables. According to a report by Research and Markets, the global fiber optic cable market is projected to reach $9.53 billion by 2026, further highlighting the critical need for effective wire pulling tools to facilitate this growth.

In the construction and electrical contracting sectors, wire pulling tools play a significant role in ensuring productive and safe installations. As the National Electrical Contractors Association (NECA) notes, skilled labor shortages are impacting project timelines and costs, making efficient tools even more critical. The use of proper wire pulling tools can reduce installation time by up to 30%, greatly improving overall project efficiency. Additionally, in the automotive industry, these tools are employed to streamline the assembly process of wiring harnesses, where precision and speed are crucial due to increasing vehicle complexity.

Overall, wire pulling tools are indispensable across multiple sectors, enabling professionals to meet the rising demands of technology and construction while enhancing safety and efficiency in their workflows.

Common Applications of Wire Pulling Tools in Various Industries

Maintenance Tips for Ensuring Longevity of Wire Pulling Tools

Wire pulling tools are essential for efficiently routing electrical wires through conduits and tight spaces. To maximize the lifespan and effectiveness of these tools, proper maintenance is crucial. According to a recent report by the Electrical Safety Foundation International, ensuring the longevity of wire pulling equipment can prevent costly replacements and disruptions in work schedules, saving contractors an average of 12% on tool-related expenses.

Regular inspections play a critical role in maintenance. Users should check for wear and tear, particularly on the pulling heads and attachments, as these components are subject to significant stress during operation. Lubricating moving parts can also help to reduce friction and prevent unnecessary damage, effectively extending the tool’s usable life. The National Electrical Contractors Association suggests maintaining a clean and organized workspace, as dirt and debris can lead to premature wear on tools and may impair functionality.

Additionally, proper storage is vital for preserving wire pulling tools. Keeping them in a designated, dry area protects them from environmental factors that could cause corrosion or deterioration. The International Association of Electrical Inspectors notes that tools stored in adverse conditions can lose up to 25% of their operating efficiency over time. By implementing these maintenance practices, professionals can ensure that their wire pulling tools remain reliable and effective for a long duration, leading to more efficient project completion and enhanced safety on the job site.

Related Posts

-

Top 5 Benefits of Using High-Quality Cable Harnesses for Your Projects

-

How to Use a Wire Snake for Effective Clog Removal in Your Plumbing System

-

Top Trends in Wire Cable Tray Solutions for 2025 You Need to Know

-

Understanding the Essentials of Wiring Looms: A Guide to Simplifying Your Projects

-

How to Choose the Best Wire Puller for Your Electrical Projects

-

How to Use Wire Ties Effectively for Organizing and Securing Items