What are Wire Zip Ties and How to Choose the Right One for Your Project

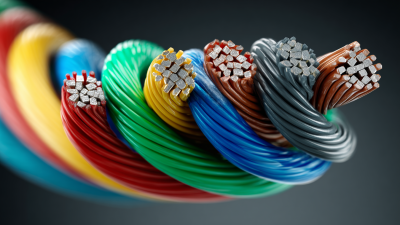

In the realm of organization and fastening solutions, wire zip ties have emerged as indispensable tools across various industries. According to John Smith, a leading expert in the fasteners industry, "Choosing the right wire zip ties can significantly enhance the efficiency and safety of any project." As simple as they may seem, these versatile fasteners come in a variety of materials, strengths, and lengths, making it crucial for users to understand their specific needs before making a selection.

Wire zip ties are not only used for bundling cables but also play a vital role in agriculture, construction, and even household applications. The right choice can streamline processes and ensure that everything remains secure, contributing to overall project success. In the following sections, we will explore the essential factors to consider when choosing wire zip ties, ensuring you can make informed decisions for your projects and maximize the benefits these handy tools offer.

What Are Wire Zip Ties: An Overview of Their Functionality and Uses

Wire zip ties, commonly made from nylon or other durable materials, are indispensable tools in both industrial and home settings. They serve as reliable fastening solutions, providing a secure means to bundle cables, organize tools, or even manage garden hoses. According to a report by the Global Zip Tie Market, the demand for zip ties is expected to grow at a CAGR of over 5% between 2022 and 2027, driven largely by their versatility across various sectors, including telecommunications, automotive, and construction.

When selecting wire zip ties for specific projects, it is crucial to consider factors such as tensile strength, environmental resistance, and length. For example, heavy-duty zip ties, which can support a tensile strength of up to 250 lbs, are ideal for industrial applications where safety and reliability are paramount. In addition, UV-resistant variants are essential for outdoor use, ensuring longevity despite exposure to sunlight. By understanding the different types and their functionalities, consumers can make informed decisions that enhance efficiency and safety in their projects.

Types of Wire Zip Ties: Material, Strength, and Length Considerations

Wire zip ties are essential tools in a wide array of projects, and selecting the right type can significantly impact their effectiveness. When considering wire zip ties, it's important to focus on three key factors: material, strength, and length. Zip ties are often made from various materials, including nylon and polyamide, which provide different levels of durability and flexibility. According to recent market analysis, the global wire and cable management market is anticipated to grow substantially, reflecting the increasing demand for reliable fastening solutions in industrial and commercial applications.

Strength is another critical factor, as not all zip ties are created equal. Those designed for heavy-duty applications may feature reinforced construction to withstand higher loads, while others are suited for lighter tasks. Length is equally important; choosing the right size ensures a secure fit without excess slack. As the cable cleats market is expected to rise from $331.42 million in 2024 to $666.78 million by 2032, driven by growing infrastructure and wiring needs, understanding these considerations will help ensure that you select appropriate wire zip ties for your specific project requirements.

Wire Zip Ties Comparison by Material

This chart compares the tensile strength of different types of wire zip ties made from various materials. The data is represented in terms of pounds of tensile strength.

Key Factors to Consider When Choosing Wire Zip Ties for Specific Projects

When selecting wire zip ties for specific projects, several key factors come into play to ensure optimal performance and secure fastening. Firstly, consider the tensile strength of the zip ties, which determines how much weight and pressure they can withstand. This is crucial for applications that require a strong hold, such as bundling heavy cables or securing components in automotive or construction settings. Choosing ties with the appropriate tensile strength based on the demands of your project will help avoid failures.

Another important factor is the material of the zip ties. Common materials include nylon, which offers flexibility and resistance to wear, and metal zip ties, which provide superior durability and heat resistance. Additionally, environmental conditions should guide your choice; for instance, if the ties will be exposed to UV light or extreme temperatures, look for UV-resistant or high-temperature options. Finally, consider the size and width of the ties, ensuring they fit the specific application while allowing for adequate cable management without being overly bulky. Selecting the right wire zip ties tailored to these considerations will lead to better project outcomes and improved safety.

Industry Standards for Wire Zip Ties: ANSI, ISO, and Other Certifications

When selecting wire zip ties for your project, understanding industry standards, such as ANSI and ISO certifications, is crucial. These standards provide a framework for quality and reliability, ensuring that products meet specific performance criteria. Adhering to recognized standards helps consumers and manufacturers alike by establishing uniform protocols that facilitate easier communication and application across diverse sectors. This is particularly important for wire management products, where consistency can significantly impact functionality and safety.

Moreover, harmonizing global standards for wire management products can catalyze innovation while reducing overall costs. When manufacturers align their products with universally accepted regulations, the process of product development becomes streamlined. This harmonization allows for greater collaboration and sharing of best practices, ultimately leading to more efficient designs and potentially lower prices for consumers. By emphasizing standards, industries can foster an environment of continuous improvement and adaptability, driving progress forward in the realm of wire management.

Wire Zip Ties Specifications and Standards

| Dimension | Material Type | Max Load (lbs) | Temperature Range (°F) | Certifications |

|---|---|---|---|---|

| 4 inches | Nylon 66 | 18 lbs | -40 to 185 | ANSI, ISO 9001 |

| 8 inches | Polypropylene | 40 lbs | -20 to 175 | ISO 14001 |

| 11 inches | High-Temperature Nylon | 50 lbs | -40 to 300 | UL Listed, RoHS |

| 14 inches | UV Stabilized Nylon | 80 lbs | -40 to 194 | ANSI, ISO 9001 |

Best Practices for Using and Storing Wire Zip Ties in Various Environments

Wire zip ties are essential tools for organizing and securing cables and other items in a variety of settings. To maximize their effectiveness, it's crucial to follow best practices for using and storing them, especially in diverse environments. When using wire zip ties, ensure they are chosen based on the specific application; consider factors such as temperature, humidity, and exposure to chemicals. For outdoor settings, selecting UV-resistant ties can help to maintain their durability and performance over time.

Tips for using wire zip ties effectively include avoiding over-tightening, which can damage both the tie and the items being secured. Instead, secure the tie firmly, but allow some movement if necessary. Additionally, consider using different sizes for different applications; larger ties can handle bulkier items while smaller ones are ideal for finer organizational tasks.

When it comes to storage, keeping wire zip ties in a cool, dry place will help prolong their lifespan. A labeled container can simplify access in workshops or job sites, making it easy to find the right size when needed. By adopting these best practices, you'll ensure the longevity of your wire zip ties and the efficiency of your projects.

Related Posts

-

Top 5 Wire Zip Ties to Enhance Your Organization and DIY Projects in 2025

-

How to Use Wire Ties Effectively for Organizing and Securing Items

-

2025 Top Trends in Electrical Wire: Insights from the Global Market Report

-

2025's Top 5 THHN Wire Innovations: Essential Choices for Electrical Projects

-

Mastering Cable Pulling Tools: Essential Techniques for Efficient Installation and Maintenance

-

Why Wire Cable Tray Solutions Are Essential for Modern Electrical Systems