Top Wiring Harness Types Explained What You Need to Know?

Wiring harnesses play a crucial role in modern electronic systems. These components bind multiple wires, providing a structured way to connect various electrical devices. Understanding different wiring harness types is essential for effective design and maintenance.

There are several types of wiring harnesses, each serving unique purposes. A good wiring harness reduces complexity and enhances safety. However, many overlook their importance until a failure occurs. It's vital to reflect on how wiring harnesses facilitate functionality in countless applications.

Choosing the right wiring harness type can save time and costs. Yet, not every application receives the attention it deserves. This can lead to flaws in design and execution. By understanding these components better, one can appreciate their significance in our daily lives.

Overview of Wiring Harnesses and Their Importance

Wiring harnesses are essential in various applications, including automotive and aerospace industries. They organize and protect wires, facilitating smooth electrical connections. According to a market research report, the wiring harness market is expected to exceed $75 billion by 2025, indicating significant growth due to rising vehicle production and technological advancements.

The importance of wiring harnesses cannot be overstated. They optimize space and enhance reliability in electrical systems. For example, modern automotive designs use complex wiring systems, where a well-crafted harness improves overall safety and performance. Yet, not all harness designs are perfect. Issues like improper insulation or inadequate strain relief can lead to failures.

Furthermore, the integration of smart technology into wiring harnesses is on the rise, yet many designs still rely on traditional methods. Around 30% of manufacturers face challenges in adapting to new technologies. Balance is crucial. Efficient designs enhance functionality but can complicate repairs. Addressing these challenges can lead to better performance and durability.

Common Types of Wiring Harnesses Used in Automotive Applications

Wiring harnesses play a crucial role in automotive applications. They serve as the central nervous system, connecting various electrical components. Different types of harnesses cater to specific needs and vehicle designs. For instance, the main harness connects elements like the battery and engine control unit. It facilitates essential functions such as starting the engine and controlling lights.

Another common type is the interior harness. This type routes electricity to dashboard instruments and multimedia systems. It enhances the driver experience by providing power for displays and controls. Sometimes, manufacturers overlook the quality of materials used. This can lead to failures, affecting vehicle safety and performance. Additionally, some harnesses are designed for environmental protection. They are more resilient to temperature changes and moisture.

Yet, not all designs are flawless. Some vehicles might face wiring issues that can be hard to detect. Problems may arise due to poor insulation or incorrect installation. These factors can lead to electrical shorts, creating significant headaches for owners. Regular inspections and good practices can help mitigate these risks.

Top Wiring Harness Types Explained What You Need to Know?

| Wiring Harness Type | Description | Common Uses | Advantages | Disadvantages |

|---|---|---|---|---|

| Main Wiring Harness | The primary harness that connects various components in a vehicle. | Connecting the engine, transmission, and other key systems. | Centralized control, organized layout. | Complex installation, potential for failure if damaged. |

| Lighting Harness | Specifically designed for the vehicle's lighting system. | Headlights, taillights, and interior lights. | Improved light performance, simplified wiring. | Limited to lighting applications, can be less durable. |

| Sensor Wiring Harness | Carries signals from various sensors to the vehicle's ECU. | Used in engine management, safety systems. | Critical for vehicle functionality, real-time monitoring. | Sensitive to interference, requires precise installation. |

| Battery Wiring Harness | Connects the vehicle's battery to the electrical system. | Powering all electrical components in the vehicle. | Ensures reliable power delivery, heavy-duty design. | Bulkier than other harnesses, may affect weight distribution. |

| Audio Wiring Harness | Connects the vehicle's audio system components. | For speakers, amplifiers, and head units. | Enhanced audio quality, easy integration. | Potential compatibility issues with aftermarket components. |

Key Materials and Components of Wiring Harnesses

Wiring harnesses are essential components in many industries, including automotive, aerospace, and telecommunications. They consist of multiple wires, connectors, and protective coverings. The materials used in wiring harnesses affect durability and performance. Common materials include PVC, polyethylene, and silicone, each offering varying degrees of flexibility and heat resistance.

According to a recent market report, the global wiring harness market is projected to reach $94 billion by 2025. This growth is driven by increased demand for advanced electronic systems in vehicles. In fact, up to 50% of a vehicle's total wiring can be attributed to the wiring harness. This statistic underlines the importance of selecting the right materials for optimal performance and safety.

Copper is the most commonly used conductor material in wiring harnesses. Its excellent conductivity makes it ideal for efficient power transmission. However, there are challenges; copper's weight can increase overall harness weight, which is problematic in applications where weight savings are crucial. The choice of insulation material is equally important, as insufficient protection can lead to failures. Balancing these factors is crucial for engineers in the design phase.

Wiring Harness Types and Their Applications

Factors to Consider When Choosing a Wiring Harness

When selecting a wiring harness, various factors come into play. Understanding your application is key. Different industries have unique requirements. For example, automotive applications demand durability due to harsh conditions. The average failure rate for wiring harnesses in vehicles can be as high as 30% if not designed properly.

Material choice is crucial. Copper is common, but aluminum offers weight savings. Be mindful of insulation types too. They can affect the harness's longevity and performance. High-temperature environments require specialized materials. A recent report indicated that nearly 40% of wiring harness failures related to insulation degradation.

Tip: Always evaluate the environment where the harness will be used. Consider abrasion, moisture, and temperature changes.

Another factor is the size and complexity of the harness. Compact designs often face assembly challenges. It's important to ensure that the harness fits the application without compromising performance. Excessive complexity can lead to errors during installation. Many engineers face such dilemmas daily.

Tip: Simplify where possible. A less complex design can save time and reduce errors.

Choosing the right wiring harness can significantly impact product longevity and reliability. The decisions you make today affect the performance of your equipment tomorrow.

Maintenance and Troubleshooting Tips for Wiring Harnesses

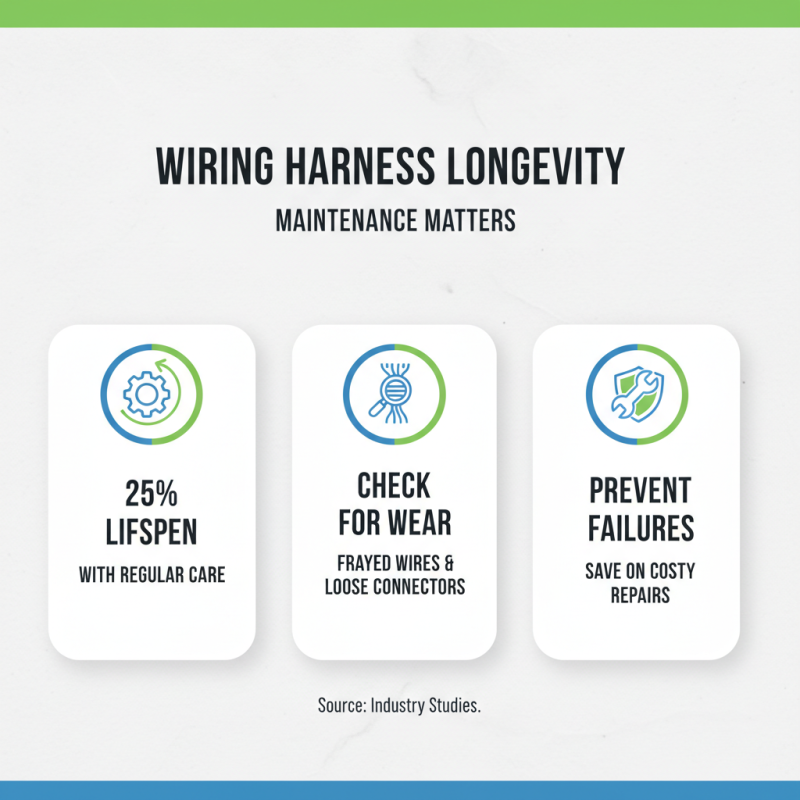

Wiring harnesses are crucial for many applications. Regular maintenance can extend their lifespan significantly. According to industry studies, a well-maintained wiring harness can last up to 25% longer than one that is neglected. Check for wear and tear regularly. Look for frayed wires and loose connectors. These can lead to failures and costly repairs.

Troubleshooting issues early is essential. If you experience performance problems, inspect the wiring harness first. A broken wire can disrupt the entire system. Many experts recommend testing the electrical connections. Use a multimeter to check voltage levels. This simple step can save time and money in the long run.

Environment plays a big role in wiring harness longevity. Harsh conditions can accelerate damage. It is vital to consider temperature, moisture, and exposure to chemicals. Reports indicate that nearly 30% of wiring harness failures are due to environmental factors. Avoiding these hazards can greatly improve performance and reliability. Stay vigilant; small issues can lead to bigger problems if ignored.

Related Posts

-

How to Choose the Best Cable Pulling Tools for Your Next Project in 2025

-

2025 How to Choose the Best Multi Conductor Cable for Your Electrical Projects

-

2025 Guide: How to Choose the Right Wire Tray for Your Projects

-

How to Choose the Best Wire Puller for Your Electrical Projects

-

Top 10 Benefits of Using a Cable Loom for Your Projects?

-

Top Trends in Wire Cable Tray Solutions for 2025 You Need to Know